|

Chapter 1. Basic Machining and Tips

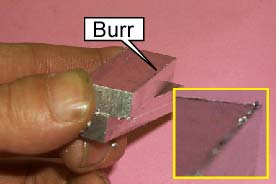

Removal of Burrs

Removing of Burrs

Removing of Burrs

| The burrs are rough edges which are generated as a result of the cutting

process. It is often called a flash in English. There are the visible burrs

as shown in Figure 1 and the invisible burrs, which are confirmed by touching

the edge. In order to make an accurate part, it is very important to remove

the burrs with a file. We must remove them carefully after the cutting

process.

|

Fig. 1, Visible Burrs

|

Removiing a Burr using File and a Wooden Surface

Removiing a Burr using File and a Wooden Surface

| It is advisable to use a wooden work surface to aid in the removal of a burr as the timber surface provides a good support while at the same time it does not damage the file if it comes into contact with the timber. Not that the file is "Pushed" along the edge and not "Pulled".

|

Fig. 5, Using a board to Facilitate the Removal of a Burr

|

Lathe Process and Removal of a Burr

Lathe Process and Removal of a Burr

| A burr can also be generated during the lathe process. It can be easy removed

by applying a file to the burr on the rotating material. Be careful to

not touch the rotating part with your finger. |

Fig. 6, Removal of a Burr after Lathe Process

|

Remove a Burr after Drilling Process

Remove a Burr after Drilling Process

| A burr generated during a drilling or tapping process is removed using

a bigger drill. A little burr can be easily removed by rotating the drill

bit by hand. Larger burrs may need to be removed by mounting the drill

bit in a drilling machine. |

Fig. 7, Removing a Burr by Hand after Drilling

|

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

Removing of Burrs

Removing of Burrs Removiing a Burr using File and a Wooden Surface

Removiing a Burr using File and a Wooden Surface Lathe Process and Removal of a Burr

Lathe Process and Removal of a Burr Remove a Burr after Drilling Process

Remove a Burr after Drilling Process Removing of Burrs

Removing of Burrs Removiing a Burr using File and a Wooden Surface

Removiing a Burr using File and a Wooden Surface Lathe Process and Removal of a Burr

Lathe Process and Removal of a Burr Remove a Burr after Drilling Process

Remove a Burr after Drilling Process