| Chapter 1. Basic Machining and Tips

Drilling

How to Use a Drill

How to Use a Drill

A drill is one of the most useful and most often used tools. Generally, a drill bit that is used metal work, has two edges with angles of 90 or 120 degrees.

Various drill bits, that have from less than 1 mm diameter to more than 40 mm diameter, are available. However, the chuck of the general drilling machines can use only shaft sizes of less than 13 mm diameter. However, for larger drills and milling machines, drill bits are designed with a "Morse" taper as shown in figure 2.

Fig.1, Drills

|

Fig.2, Taper Drill

|

Machines for Milling and Drilling Machines for Milling and Drilling

Figures 3 to 5 respectively pictures a drilling machine, a milling machine

and a hand drill. Hand drills are only advised when a high degree of accuracy

is not required or it is not practical to mount the work piece in the drilling

machine. |

Fig.3, Drilling Machine

|

Fig.4, Milling Machine

|

Fig.5, Hand Drilling Machine

|

|

Wheting of Drill

Wheting of Drill

To achieve accuracy of drilling, the drill bit must be sharp. The bigger

drills, such as 6 mm diameter plus, can be wheted (sharpened) using a bench

grinder. However, it can be a very difficult process and much practice

is needed for the beginner.

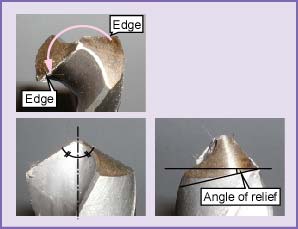

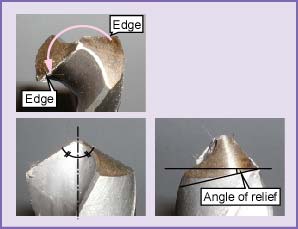

Fundamentally, in the wheting process, two edges of the drill have to touch

the grinding medium at the same time.

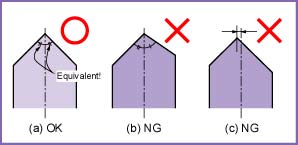

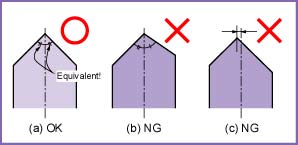

The first step in the whetting proves is to grind the two sides of the

drill to an equal angle as shown in figure 7(a). Note, if the angle of

both each side is not even as in figures 7 (b) and (c), the drill will

not provide a satisfactory cut.

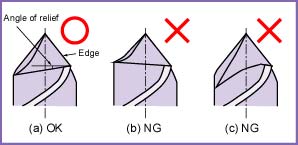

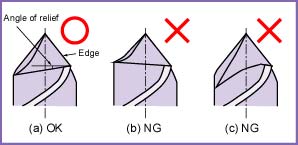

The second step involves grinding to make an "angle of relief"

as shown in figure 8(a). Note that if a drill bit does not have an angle

of relief, than it is not possible for the drill to drill a hole in the

work piece. An example of incorrect angles of relief can be seen in figures

8 (b) and (c). |

Fig.6, Edges of a Drill

|

Fig.7, Angles of Edges

|

Fig.8, Angle of Relief

|

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

How to Use a Drill

How to Use a Drill Wheting of Drill

Wheting of Drill

Machines for Milling and Drilling

Machines for Milling and Drilling