| Chapter 1. Basic Machining and Tips

Marking-off and Drilling a Cylinder

Drillings of Circular Holes

Drillings of Circular Holes

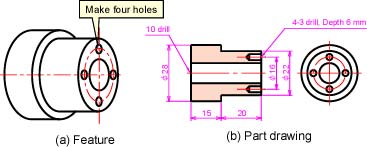

In any mechanical parts, we often drill holes on a circular pattern on

the face of a cylindrical as shown in Figure 1.

Figures 2 to 7 shows the procedure of a marking-off and drilling on a typical

part. |

Fig.1, Part Drawing

|

Fig.2, Marking the Center Lines on the Work Piece

| The work piece is set on a square block and securely fastened in the "vee"

section. Find the center of the work piece and scribe a vertical a line

across the face. Care must be taken to find the exact center otherwise

the desired accuracy cannot be obtained. |

|

Fig.3, Markings of Center Lines (continued)

| Turn the square block 90 degrees and mark the line across the face as it

step one to achieve the intersecting line. |

|

Fig.4, Marking with a Center Punch

| Find the center of each line at the exact location to be drilled and using a center punch and hammer, lightly mark the drilling position. Check the dimensions and if they are correct, re-punch the marks but this time using a bit more force. |

|

Fig.5, Marked-off Material

| The marking-off process is complete and the work piece is ready to be drilled. |

|

Fig.6, Processing of a Drilling Machine

| Secure the work piece in the drilling machine vice and drill the holes. |

|

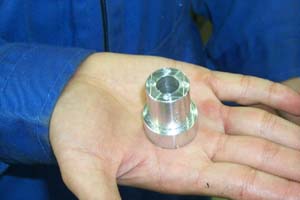

Fig.7, Completed Part

|

Using V-shaped Block

Using V-shaped Block

A V-shaped block as shown in Figures 8 and 9 is used for the marking-off

of a cylindrical part. Note, the vee block shown does not have a securing

clamp so it is not as convenient to use as one with a clamp.

Fig.8, V-shaped Block

|

Fig.9, Setting of a part on the Block

|

|

[ Metal Working TOP ][ Hirata HOME ][ Power and Energy Engineering Division ][ NMRI HOME ]

|