|

Chapter 1. Basic Machining and Tips

Machining Flowchart

Thinking about Machining

Thinking about Machining

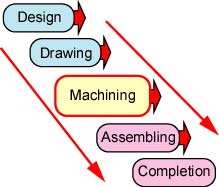

| Let us consider the steps involved in creating a mechanical device to solve a

given problem (Fig. 1). The first step is conceptual development (the design

stage). Next we lay out an assembly plan and draft the plans for each part (the

drawing stage). Then the individual parts are machined. Finally, the device is

assembled. |

Fig. 1. The Overall Process

|

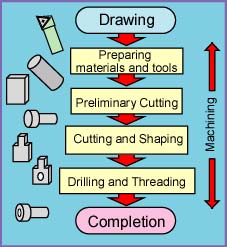

Please note that the entire process is far more than just working with machine

tools! After reviewing the plans, we must consider how we will machine

each part. Then we must prepare materials, tools, and jigs and fixtures, if

needed. We begin by cutting the material to rough size. Then we machine the

pieces on the cutting and shaping tools (the lathe and mill). Finally, we add

the finishing touches, such as drilling holes or cutting threads.

The most important step is to plan the machining of each individual part.

Naturally, the process differs from part to part. The shape of the part, the

material used, and the accuracy required all contribute to the plan. |

Fig. 2. Details of Machining

|

Efficient Machining

Efficient Machining

In machining, it is important to make an accurate part. In industry, it is also

required to make a part quickly. It is clear that an expert will take

less time than a beginner. But the operating time of a machine tool is not so

different between the expert and the beginner, because the machining time is

bounded. For efficient machining, it is important to plan your work

operations ahead of time. Please note that a beginner should not rush a

machining operation, as rushing increases the chance of making a mistake.

Mistakes have to be corrected, or the piece abandoned, taking more time rather

than less. |

Cutting Process and Die-Casting Process

Cutting Process and Die-Casting Process

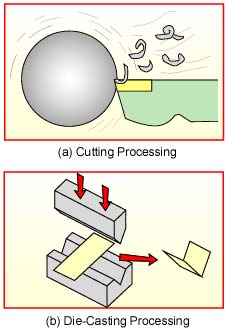

Cutting and die-casting are typical machining processes. The cutting process

uses a sharp blade to remove a portion of the material. One of its

characteristics is that metal waste is generated. The lathe and the mill are

typical cutting machines. We can make various parts using a cutting machine.

They are thus suitable for making one-time items such as experimental

equipment.

On the other hand, the die-casting process makes use of the ductile properties

of metals. It produces no waste, and thus it is suitable process for mass

production. However, a given die-casting pattern can produce only one specific

part. It is not suitable for one-time items.

(The contents of this web site describe only the cutting process. The author is

not knowledgeable in die-casting and mass production.) |

Fig. 3, Cutting Process and Die-Casting Process

|

[ Metalworking TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

Thinking about Machining

Thinking about Machining Cutting Process and Die-Casting Process

Cutting Process and Die-Casting Process Thinking about Machining

Thinking about Machining Cutting Process and Die-Casting Process

Cutting Process and Die-Casting Process