| Chapter 1. Basic Machining and Tips

Metal Materials

Materials

Materials

There are many different material types to choose from when undertaking

a project. For the purposes of our discussion, the materials are grouped

roughly into two categories, these being "Non-metallic" and Metallic".

In respect to metallic materials these are then subsequently grouped into

two groups being ferrous and non-ferrous. Each of the materials has their

own characteristics and requires different machining techniques. Careful

consideration needs to be given to the correct material selection for its

application. (Definition: Ferrous as in containing Iron, e.g steel - Non-ferrous

as in not containing Iron e.g aluminium, copper) A simple test for ferrous/non-ferrous

materials is to use magnet as a magnet will sick to ferrous materials due

to its iron content.

Aluminium Alloy Aluminium Alloy

There are many kinds of Alloys to choose from but often, Aluminium is chosen

as it is lightweight (about 2700 kg/m3 density), it is comparatively soft

and its process-ability is good. From a machining viewpoint pure aluminium

(JIS A1000) greatly differs from Al-Cu alloy (JIS A2000) .

Pure aluminium is easy to bend but it is difficult to process as it is

too soft and easily clogs cutting tools. On the other hand, the Al-Cu alloy,

such as A2011 or A2017 (called duralumin) is easy to handle and cut with

several of the grades having strength similar to that of steel. However,

one of the drawbacks of aluminium is that it is difficult to weld, solder

and bend.

It is very difficult to distinguish between the pure aluminum, the Al-Cu

alloy and etc. When they are cutting with a machine, we may recognize the

material. |

Fig.1, Aluminum Alloy (JIS A2017)

|

Stainless Steel

Stainless Steel

A typical stain less steel is JIS SUS304. The benefits of stainless steel

is that it has high strength, great heat-resistance, and and it resists

staining e.g rust. Due to its high resistance to heat it makes an ideal

material for mechanical parts that are subjected to heating such as a heater

of a Stirling engine. Also, due to the materials resistance to rusting,

it is ideal for use where it is exposed to water. Other examples of its

use is in drive shafts where both strength and corrosion resistance is

needed.

Stainless Steel tends to be a bit sticky in respect to cutting and machining and as it is a relatively hard material it tends to shorten the life of the cutting tools being used. Such cutting tools need to be sharpened often particularly in prolonged cutting operations. Stainless Steel can usually be identified by its glossy silver colour. |

Fig.2, Stainless Steel (JIS SUS304)

|

Carbon Steel Carbon Steel

Typical carbon steel materials are JIS S45C and JIS SS400. They are very

cheap, excelling in weldability, and they can be subjected to various heat

treatments. Since many machine tools are designed to cut mild steel material,

it is very rare to encounter problems while machining.

I hardly use mild steel apart from cases where welding is required as I

mostly make experimental models as therefore issues such as low manufacturing

costs are not a consideration in the work that I do.

Generally, mild steel has a black surface and this surface is very hard,

if possible, this surface should be left intact as it offers additional

protection. |

Fig.3, Carbon Steel (JIS S45C)

|

Brass

Brass

Brass is an alloy which is made from a combination of copper and zinc as the main ingredients. In compared with carbon steel or stainless steel, the machine-ability of brass is good, and it also has good soldering properties.

Brass is very heavy due to its high density so it is ideal for heavy parts,

such as a flywheel or balance weight for model engines.

Brass is prized for the highly polished finish it can produce however,

since brass surface will oxidise when exposed to the elements, it it preferable

to apply a clear lacquer protective coating.

Brass is very expensive when compared to other materials so it is used

very selectively. |

Fig.4, Brass (JIS C2800)

|

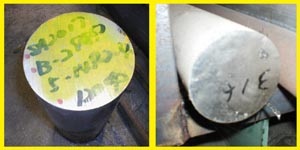

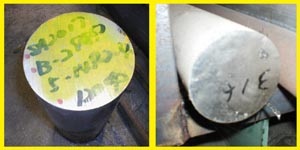

Material Identification Material Identification

Usually, a billet (column) of material is sold in unit lengths of 1 to 2 meters (or more). These billets typically carry the material identification written on the end of the billet as seen in the photos on the right. As the billet is usually cut to provide the work piece, take care to cut from the end opposite the markings so as to leave the markings for subsequent identification.

|

Fig.5, Material Indication

|

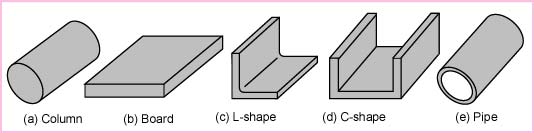

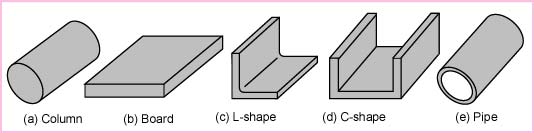

Common Shapes Common Shapes

Material is usually supplied as common shapes and these are (a) Billets

(columns), (b) flat bar (boards), (c) Angle (L-shaped), (d) "C"

channel (C-shaped) and (e) pipe. The correct selection of material assists

in simplifying a project.

Fig.6, Common Material Shapes

Common machining sizes of billets Common machining sizes of billets

Common billet sizes are: 30mm, 40mm, 50mm, 60mm and 80mm (However many

other sizes can be ordered). As the surface finish of many billets is not

satisfactory for a finished project, they often have to be machined to

suit the project. Should you want a finished diameter of the above mentioned

sizes, then it is necessary to commence with the next larger size in the

range and machine this down to the desired diameter. The exception to this

can be stainless steel with diameters of 10mm or less as the surface finish

of these is quite high and sometimes suitable for the job in hand. |

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

Materials

Materials Aluminium Alloy

Aluminium Alloy Stainless Steel

Stainless Steel Carbon Steel

Carbon Steel Brass

Brass Common Shapes

Common Shapes