| Chapter 3. How to Use a Lathe Making Accurate Parts

Lathe Processing and Accuracies

Lathe Processing and Accuracies

There are many issues that can affect the process, such as parallel faces,

surface roughness, warping of circle and offset of the center. In the following,

we consider the accuracies in lathe process.

Making of High Surface Roughness

Making of High Surface Roughness

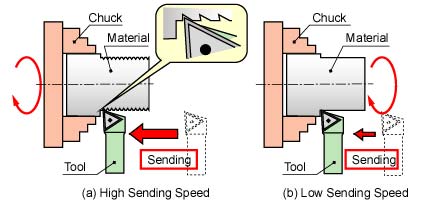

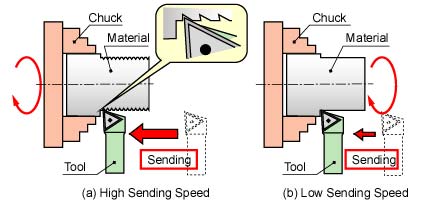

| In the Lathe process, we often need to achive a high surface finish. In

such cases, the basic principles of the process are: the rotating speed

should be set high and the sending speed should be set low. Because when

the sending speed regarding the rotating speed is too high, the edge of

the cutting tool leaves scars on the material. |

Fig.1, Sending Speed and Surface Roughness

|

Re-Chucking and Offset

Re-Chucking and Offset

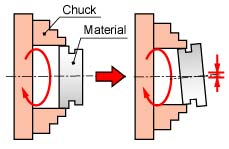

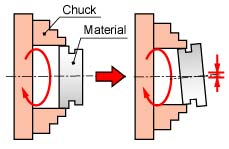

| When a mechanical part is required to not have an offset of the center,

we should not re-chuck the material. In other words, the material must

not remove from the chuck until finishing of the cutting. The re-chucking

brings the offset of the material. We should determine the correct procedure,

which should not require the part to be re-chucked, or should consider

using a jig. |

Fig.2, Re-chucking and Offset

|

Processing of Shallow Shaft

Processing of Shallow Shaft

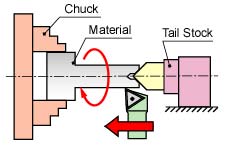

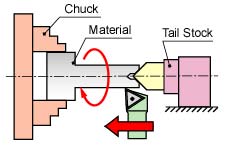

In the case of the cutting for a long and slender part, we should use a

tail stock as shown in Figure 3. The tail stock is inserted into a hole

drilled into the center of the piece. Generally the hole is drilled using

a special drill, called a center drill.

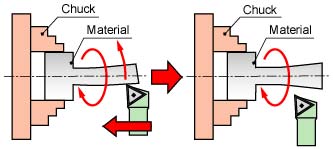

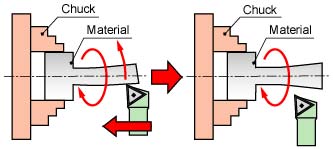

However, when the diameter of the piece is too small, we often cannot use

the tail stock, because it comes into contact with the cutting tool. In

such cases, the cutting material has a taper as shown in Figure 4. Because

the material does not have enough rigidity to withstand the cutting process.

In order to remove the taper, the cutting depth should be set to small

cuts, and we repeat the cut with the same position of the tool. Also it

is important to measure the diameters in detail.

Fig.3, Using of Tail Stock

|

Fig.4, Processing of Shallow Shaft

|

Making of Accurate Diameter

Making of Accurate Diameter

In the case of finishing with 1/100 to 5/100 mm of accuracy, the scales

of the lathe is not sufficient accurate. In such cases, we should finish

to a medium surface, and continue to measure the size of the piece until

the desired finish and size is achieved. Do not hurry and exercise extreme

patents. |

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

Lathe Processing and Accuracies

Lathe Processing and Accuracies Making of High Surface Roughness

Making of High Surface Roughness Re-Chucking and Offset

Re-Chucking and Offset Processing of Shallow Shaft

Processing of Shallow Shaft

Making of Accurate Diameter

Making of Accurate Diameter