| Chapter 3. How to Use a Lathe

Using a Cut-off Tool

Cutting-off Tool Cutting-off Tool

A cutting-off tool, which is often called a parting tool or grooving tool,

is one of the important cutting tools for the lathe processing.

Generally, the cutting-off tool touches to the material vertically, and

is moved to the vertical direction only. As a fundamental rule, it must

not be send the side direction, because its point is thin and weak.

Also, in the case of using the cutting-off tool, the rotating speed and

the sending speed must be lower, and the cutting depth must be small compared

with the general processing using the side tool. Please note that it is

needed much cutting oil in during the processing. |

Fig.1, Cutting-off Tool

|

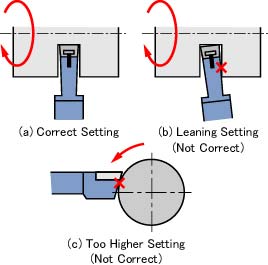

Setting of the Cutting-off Tool

Setting of the Cutting-off Tool

The side faces of a cutting-pff tool is near parallel, thogh the edging

point is somwhat thick. When the tool set with a small leaning as shown

in Figure 2(b), the side face touchs to the material. If we notice a bad

shapeness or a bad sound, we must reset the leaning of the tool in careful.

When the cutting-off tool is set higher than the center of a material as

shown in Figure 2(c), the edge does not touch the material. The cutting-off

tool should be set to little lower than the center, as the same of a side

tool. Of course, a fundamental rule is that the height must be the same

of the center of the material. |

Fig.2, Setting of Cutting-off Tool

|

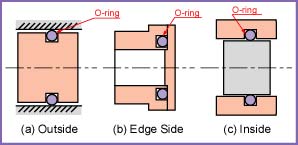

A Slot of O-ring

A Slot of O-ring

An O-ring is one of the seal dedvices, and used in many machines treating

gas or liquid fluid. Because it is very reasonable and standardized suitably.

The O-ring is installed into a slot as shown in Figure 3. When the O-rong

is installed around the outside surface as shown in Figure 3(a), the slot

can be make easily using the cutting-off tool. Figures 4 and 5 show the

examples of using O-rings. |

Fig.3, Installings of O-ring

|

Fig.4, O-ring Slot of a Fish Robot

|

Fig.5, O-ring Tire of a Model Wheelchair

|

ADDITION: Making of an O-ring Slot at Edge Surface and Inner Surface

ADDITION: Making of an O-ring Slot at Edge Surface and Inner SurfaceWhen we make an O-ring slot at an edge surface as shown in Figure 3(b),

a special tool, of which look is similar the cutting-off tool, is used.

The edge of the tool is touched to the surface as shown in Figure 6, and

it is sent to the left slowly. The side face of the tool must not touch

the material, then it is too difficult to make a slot for a small O-ring.

Also the diameters of the slot are not accurate generally, then the way

of Figure 3(a) is better if possible. |

Fig.6, Slot for a O-ring installed Edge Surface

|

| When we make an O-ring slot at an inner durface as shown in Figure 3(c),

a special tool asn shown in Figure 7 is used. The processing of using the

tool becomes too hard. |

Fig.7, A Special Tool for an Inside Slot

|

Fins of a Stirling Engine

Fins of a Stirling Engine

Thermal engine, such as a Stirling engine, often has fins for cooling. Because the large area of heat transfer brings high performance.

The fins shown in Figure 8 can be created by the parting tool (prooving

tool). Please note that deep and thin fins need hard processings. |

Fig.8, A Stirling Engine with Fins

|

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

Cutting-off Tool

Cutting-off Tool A Slot of O-ring

A Slot of O-ring Fins of a Stirling Engine

Fins of a Stirling Engine Cutting-off Tool

Cutting-off Tool A Slot of O-ring

A Slot of O-ring Fins of a Stirling Engine

Fins of a Stirling Engine