| Chapter 3. How to Use a Lathe

Using a Four-jaw Chuck

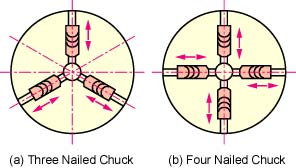

Three-jaw Chuck and Four-jaw Chuck

Three-jaw Chuck and Four-jaw Chuck

A material into a chuck of a lathe is fixed by compressing jaws. A typical

chuck has three jaws. Because, in the general turning processing, we make

a column part as the center of a material. Then the three-jaw chuck is

very convenient.

On the other hand, when we make an offset part, or drill an offset hole,

a four-jaw chuck is often used. In the case of the four-jaw chuck, the

position of each jaw can be adjust optionally, and the chuck can fix the

material optional position. But it is difficult to adjust the position

of the material. Also it is not efficient, because a lot of time is needed

for changing of the chuck. The four-jaw chuck is not used always except

unavoidable cases. |

Fig.1, Three-jaw Chuck and Four-jaw Chuck

|

Making a Hole at the Offset Position

Making a Hole at the Offset Position

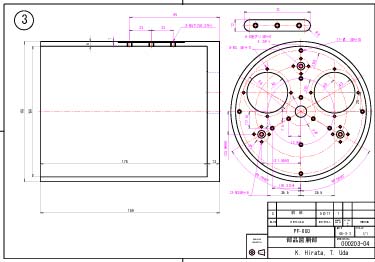

| Figure 2 shows the body of a fish robot, PF-600. It has two offset holes

at the edge surface. The holes need high roughness and high accuracy of

diameter. Because the holes are waterproofed using O-rings. In such cases,

a drilling is not suitable. Then it is needed to use the four-jaw chuck

and boring processing. |

Fig.2, Part Plan (a Body of Fish Robot, PF-600)

|

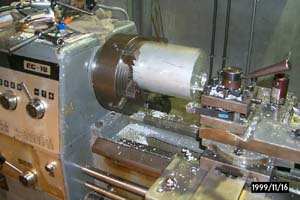

Fig.3, Setting to Four-jaw Chuck

| A four-jaw chuck is set to a lathe for making of offset holes. |

|

Fig.4, Boring Process

|

Using a Boring bar, the surface is finished a high roughness.

|

|

Fig.5, One Completed Hole

| One hole is finished, and another is processing. |

|

Fig.6, Offset Holes

| The part has many threads, so it is very complex. |

|

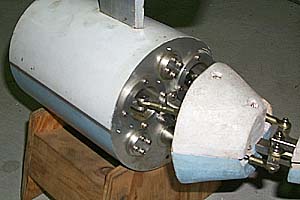

Fig.7, Assembled Parts

| The body is completed and assembled to the other parts. |

|

Fig.8, Fish Robot, PF-600

| The fish robot, PF-600 is swimming well, without water leakage. |

|

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

Three-jaw Chuck and Four-jaw Chuck

Three-jaw Chuck and Four-jaw Chuck Making a Hole at the Offset Position

Making a Hole at the Offset Position Three-jaw Chuck and Four-jaw Chuck

Three-jaw Chuck and Four-jaw Chuck Making a Hole at the Offset Position

Making a Hole at the Offset Position