| Chapter 3. How to Use a Lathe

Making a Screw with a Lathe

Make a Screw with a Threading Tool Make a Screw with a Threading Tool

Generally, threads are made with a tap and a die. But we can make threads with a lathe, when the threads has special sizes, or we do not have a suitable tap or die.

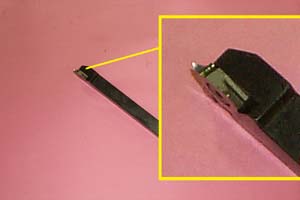

When a male thread is made with the lathe, a threading tool as shown in

Figure 1 is used. This tool has a tip, which has the edge of 60 degrees.

With this tool, the material is cutting in several times, at the same position,

and at the same pitch. When the cutting depth becomes the decided value

geometrically, the thread is completed.

The threading is one of the very difficult processings. If we have a little failed operation, the tool or the lathe is damaged. It is important to have many experiences, but a beginner should not thread with the lathe thoughtlessly. |

Fig.1, Threading Tool (For Male Screw)

|

Cautions for the Threading Processing with a Lathe

Cautions for the Threading Processing with a Lathe

(1) The threading must repeat the sendings at the same positions. Figure

2 shows scales of lathes for the threading. We must set the scale, and

repear the sendings. Also we should confirm the threading operation with

a handling description of the lathe, because the operation is difference

by each lathe.

Fig.2, Scales for the Threadings

(2) We should set the pitch of the thread. For the setting of thepitch,

the lever or the gears of the lathe may be be changed.

(3) Generally, the sending must be stopped on the way. Then the material

must have a slot for the stopping (see Figure 6). Also we should set as

low rotating speed as possible, because the stopping is easy. |

Example: Making of a Male Thread for a Video Camera

Example: Making of a Male Thread for a Video Camera

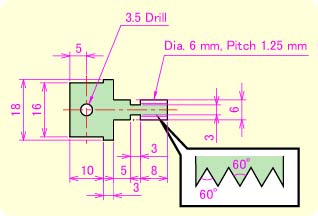

| Follows example is a making a male thread for a video camera. The thread

has about 6 mm of outer diameter, and 1.25 mm of pitch. This thread is

called 1/420UNC. We did not have the die, so we made the thread with a

lathe. |

Fig.3, Part Drawing

|

Fig.4, General Turning

| At first, the material is finished the outer diameter using a side cutting

tool. |

|

Fig.5, Making of a Slot

| A slot is made by a cut-off tool. In this case, the depth of the slot is

1.5 mm, and the width is 3 mm. |

|

Fig.6, The Slot for the Stopping

| The slot is wide for safe. |

|

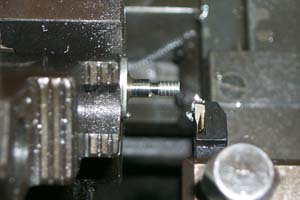

Fig.7, Threading

| This is the threading processing. In the operation, we have strong strain,

because the tool must be stopped in the slot. |

|

Fig.8, Completed Part

| The thread is completed, tough it is not beautiful. |

|

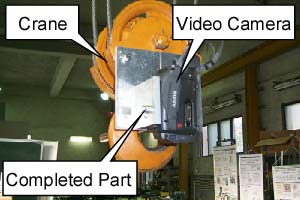

Fig.9, A Video Camera

| The video camera is set to a crane with the thread. |

|

Fig.10, Installed Video Camera

| The video camera can take pictures at 5 m of height. |

|

Fig.11, Consecutive Photogragh

| This photogragh shows a locus of an experimental model wheelchair. |

|

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

Make a Screw with a Threading Tool

Make a Screw with a Threading Tool Example: Making of a Male Thread for a Video Camera

Example: Making of a Male Thread for a Video Camera Make a Screw with a Threading Tool

Make a Screw with a Threading Tool Example: Making of a Male Thread for a Video Camera

Example: Making of a Male Thread for a Video Camera