| Chapter 3. How to Use a Lathe

How to Use a Jig

Necessaries of Jig

Necessaries of Jig

A Jig is an assistance equipment for machinings and it is neccesary for

the machinings. Generally, a jig is used when a part has complex shape,

or when a making part is difficult with a general turning.

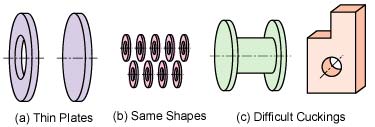

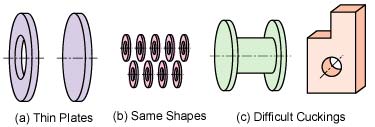

Figure 1 shows typical examples which are made using jigs, such as thin

plates, the same shaped many parts and hard chucking parts. |

Fig.1, Example Parts using Jigs

|

Procedure of Making Thin Plates

Procedure of Making Thin Plates

| Now, we would like to make a thin plate, which has 28 mm of outer diameter,

2 mm of thickness and 6 mm of diameter hole at the center. The thin plate

cannot be chucked at a lathe. Therefore we prepare a simple jig as shown

in Figure 2(a). |

(a) Jig

| The point of this jig has 6 mm of outer diameter, 3.5 mm of length and

a M4 male thread. |

|

(b) Prepared Materials

| Aluminum plates with 2 mm of thickness are drilled 6 mm of hole. And their

edge is cut off roughly. |

|

(c) Chucking to a Lathe

| The plates are set to the jig, and chucked a lathe. |

|

(d) Cutting of Sjapes

| The plates are cut with a side tool little by litte, A big cutting dedpth

bring a slip between the material and the jig. |

|

(e) Completed Plates

| The plates are finished. The simple jig is very useful for the processing. |

|

Fig.2, Procedure of Making Thin Plates Using a Jig

Boring Process of a Board Boring Process of a Board

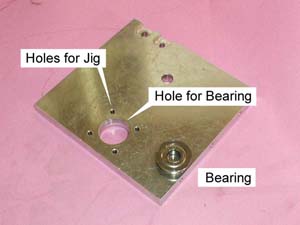

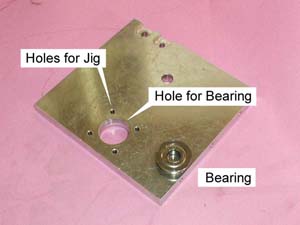

Now, we would like to make a hole on a board. The hole is used for a bearing,

then it is needed a high acuuracy. In such cases, the board can not be

set to a general three-jaw chuck. A drill may be used for the making of

the hole, but the drilling hole does not have the accuracy. Then we prepere

a simple jig as shown in Figure 3(a). As shown in Figure 3(b), the board

is drilled holesfor the jig, and the board is set to the jig. Next, the

jig is set to the lathe, and the accurate hole for the bearing is made

with a boring bar.

(a) Jig

|

(b) Completed Part

|

Fig.3, Boring Process of a Board

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

Necessaries of Jig

Necessaries of Jig Procedure of Making Thin Plates

Procedure of Making Thin Plates Boring Process of a Board

Boring Process of a Board