| Chapter 4. How to Use a Milling Machine

Using an End Mill

What is the End Mill?

What is the End Mill?

An end mill as shown in Figure 1 is one of the indispensable tools in the

milling processing. The end mill has edges in the side surface and the

bottom surface. The fundamental usage is that the end mill is rotated,

and makes a plane of a material in the right-and-left direction or a plane

of a bottom side of the end mill. We can make various shapes of mecahnical

parts with the end mill.

The edge of the end mill is very weak. In case beginning o‚† cuttings,

we have to take care so that the end mill may touch to a material as slowly

as possible. |

Fig.1, End Mill

|

End Mill with Throw Away Tips

End Mill with Throw Away Tips

Figure 2 shows an end mill with throw away tips. When the tips have bad

sharpness, they can be changed easily. Ant it gets good sharpness again.

|

Fig.2, End Mill with Throw Away Tips

|

|

Three Important Elements for Milling

Three Important Elements for Milling

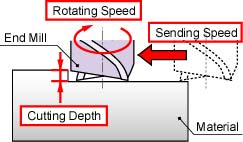

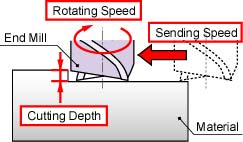

In the case of the milling process, the rotating speed, the cutting depth and sending speed are very important. These imporatnt elements are affected by the materials, the shapes and the roughness of the surface and etc. Generally, in order to get the high roughness, the cutting depth must be set to small, and the sending speed must be set to low.

If you don't know the values ...

If you don't know the values ...

If you do not know the suitable values of the three elements, you should

set a small cutting dedpth, a low sending speed and a low rotating speed

for safety. |

|

Fig.3, Three Important Elements

|

Automatic Sending Automatic Sending

A general milling machine has an automatic sending mode. This is veru conbenient and to get efficient processing. But it is too dangerous that a beginner may often send the table to the opposite direction. Please use the automatic sending mode after enough experiences. |

Procedure of Milling Processing

Procedure of Milling Processing

For an example of the milling processing, a mechanical part is made by

the milling machine in followings.

(1) Cut Board Material

| A material was cut by a band saw. The size is bigger about 3 mm than the

final size. |

|

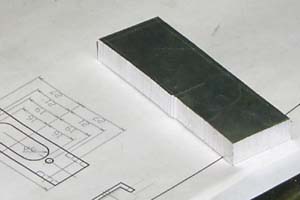

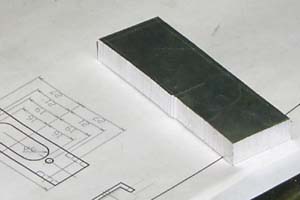

(2) Cutting of Bottom Surface

| The material is cut with the bottomedge of the end mill. In such ways, two face of the material can be cut. |

|

(3) Cutting of Side Surface

| The material is cut with the side edge of the end mill. When the vise is

set in the vertical position accurately, the material can be get the accurate

rectangle easily. |

|

(4) Shaped Part

| The material is shaped with the end mill. Since it has a complex shape,

we are careful in the processing. |

|

(5) Drilling

| The tool is changed from the end mill to a drill. |

|

(6) Completed Part

| This is a completed part. It is not so simple shape, but the milling process

is not so difficult. |

|

Fig.4, Procedure of Milling Processing

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

What is the End Mill?

What is the End Mill? Three Important Elements for Milling

Three Important Elements for Milling Procedure of Milling Processing

Procedure of Milling Processing

End Mill with Throw Away Tips

End Mill with Throw Away Tips