| Chapter 5. Weldings and Soldering

Arc Welding

Outline of Arc Welding

Outline of Arc Welding

The arc welding makes arcs between a material and a welding rod. And it

is a well used welding method. In the arc welding, we use a torch with

a welding rod as shown in Figure 1. And both of the material and the welding

rod are ment in the arc. The arc welding is very high speed, and if the

welding is very well, the strength is very high. But the arc is very light,

then we cannot see the welding processes. A beginner may be often failed

the welding.

All weldings, including the arc welding, need higher technique than cutting

processings, because we do not have the same conditions. |

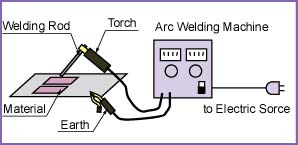

Fig.1, Hand Torch for Arc Welding

|

Actual Arc Welding Actual Arc Welding

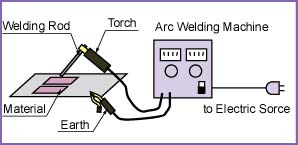

| As shown in Figure 2, An arc welding machine is connected to electric cables

to the electric source, the torch and the material (earth). After switch

on the machine, the welding rod is touched to the material, and the arc

occures. The basic handling of the arc welding is in follows. |

Fig.2, Arc Welding System

|

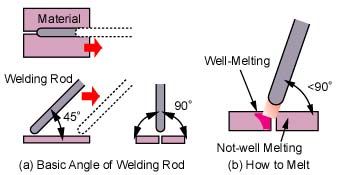

Angle of Welding Rod

Angle of Welding Rod

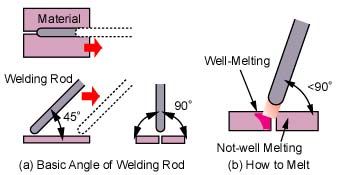

In the arc welding, it is important to set the angle of a welding rod (coated

electrode).

As the most fundamental welding, the case where two griddles (mother material)

are welded in the shape of [ of a transverse direction ] a straight line

is considered. It welds laying down about 45 degrees of wedding rods in

the direction of the right (in the case of a right-handed person) from

the left, as shown in Fig. 3 (a). And it is the foundations which are maintained

at the same angle (90 degrees) to two griddles.

最も基本的な溶接作業として,2枚の鉄板(母材)を横方向の直線状に溶接する場合を考える。図3(a)に示すように,左から右の方向(右利きの場合)に,溶接棒を45°程度寝かしながら溶接する。そして,2枚の鉄板に対して同一の角度(90°)に保つのが基本である。

As shown in Fig. 3 (b), when a wedding rod is leaned, a material opposite to the leaned side becomes easy to melt. Welding is advanced checking that both of material melts uniformly using this.

図3(b)のように溶接棒を傾けた場合,傾けた側と反対の材料が溶けやすくなる。これを利用して,両方の材料が均一に溶けることを確認しながら溶接を進める。 |

Fig.3, Angle of Welding Rod

|

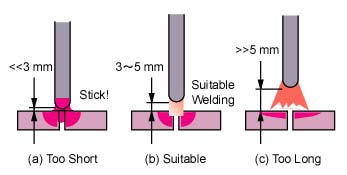

Distance between the Welding Rod and Material

Distance between the Welding Rod and Material

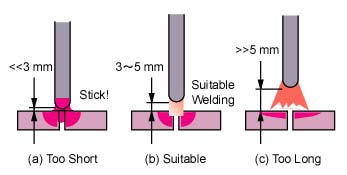

You have to keep constant the interval of a wedding rod tip and mother

material during welding. As a standard, the distance is about 3-5mm. If

an interval approaches too much and a wedding rod and mother material contact,

an arc stops occurring and a wedding rod and mother material will adhere

depending on the case. Moreover, if an interval separates too much, an

arc will be distributed and suitable welding cannot be performed. Since

a wedding rod becomes short as it advances welding, it warns to keep the

interval of a wedding rod and mother material suitable.

溶接中,溶接棒先端と母材との間隔を一定に保たなければならない。目安として,その距離は3~5mm程度である。間隔が近づきすぎて溶接棒と母材とが接触すると,アークが発生しなくなり,場合によっては溶接棒と母材とがくっついてしまう。また,間隔が離れすぎるとアークが分散され,適切な溶接ができない。溶接棒は溶接を進めるに従って短くなるので,溶接棒と母材との間隔を適切に保つように注意する。 |

Fig.4, Distance between the Welding Rod and Material

|

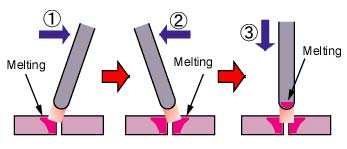

Movements of Welding Rod

Movements of Welding Rod

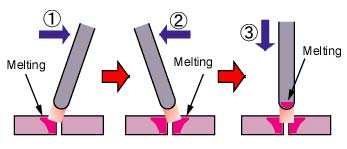

What is necessary is generally, just not to necessarily move a wedding rod straightly. The wedding rod is buried in the meantime, checking that two mother material has melted firmly. The rhythm which leans (1) wedding rod and melts the material of one side as an image and which melts (2) another material of pushing in (3) wedding rod will be repeated.

一般に,溶接棒をまっすぐに動かせばよいわけではない。2つの母材がしっかりと溶けていることを確認しながら,その間に溶接棒を埋めていく。イメージとして,①溶接棒を傾けて片側の材料を溶かす,②もう一方の材料を溶かす,③溶接棒を押し込む,といったリズムを繰り返すこととなる。 |

Fig.5, Imagine of Arc Welding

|

Adjustment of Electric Current

Adjustment of Electric Current

In the arc welding, the adjustment of an electric current is very important.

If the electric current is too low, the materials are not melted enough.

Also the arc does not often birth, and the welding rod fixes to the material

easily. Oppositely, if the electric current is too high, the materials

are melted excessively, and a hole is often made at the welding point.

Examples of Arc Welding

Examples of Arc Welding

When an equipment is made by constructed channel materials, we can make

it with bolts and nuts. However if we can handle the arc welding, the processing

has more shorter time and easy building. Figure 6 shows an example of the

experimental equipment using the arc welding.

(a) Cutting of the materials

|

(b) Completed Waving Table

|

Fig.6, Waving Table for Model Wheelchairs

[ Metal Working TOP ]

[ Hirata HOME ]

[ Power and Energy Engineering Division ]

[ NMRI HOME ]

|

Outline of Arc Welding

Outline of Arc Welding Actual Arc Welding

Actual Arc Welding Adjustment of Electric Current

Adjustment of Electric Current Examples of Arc Welding

Examples of Arc Welding