What is a Semi Free-Piston Stirling Engine?

What is a Semi-free-piston Stirling Engine?

What is a Semi-free-piston Stirling Engine?

A displacer piston, often moved in the same cylinder as the power piston, is located in a separate cylinder and may be moved by a small electric motor. The input power to the electric motor is very small, because a pressure differential on both side of the displacer piston is very small. When the displacer piston is moved, the pressure in the engine changes and the gas is allowed to force the power piston to move. If the displacer piston is driven to oscillate, and the frequency of the displacer piston equals to the resonant frequency of the power piston, the stroke of the power piston becomes progressively greater. This works on the same general principle as Stirling engine.

Characteristics of the Semi-free-piston Stirling engine are that the output power can be used directly from the oscillating motion of the power piston, and it does not have or need a flywheel.

Typical thermal engines change energy obtained from reciprocating motion of the piston to a rotary motion through a crank mechanism. The rotary motion is suitable for a screw propeller of a ship. However, in the case of the fish robot, the piston can drive the tail assembly directly. A great deal of mechanical frictional loss can thus be avoided which would result in high potential for efficiency.

Since the driving action needed is not rotary motion, but an oscillating push-pull action, this type of engine has several potential advantages. Energy is not wasted in converting motion to rotary action, no gear reduction frictional losses are encountered and rotary action need not be re-converted back into push-pull oscillating motion needed to power the tail assembly. Savings in weight and parts count tend toward greater reliability. The Stirling engine does not need precise timing and control of explosive events such as with diesel or gasoline engines. The heat it requires for power may be produced by any means available, such as a controlled constant flame.

One of the main problems in applying the Semi-free-piston Stirling engine to the fish robot is that of size. A classical Stirling engine operates at engine speed of 1500 to 2000 rpm (25 to 33 Hz) approximately. The Semi-free-piston Stirling engine to the fish robot has operating frequency of 3 to 5 Hz. As the operating frequency decreases, the pistons must become larger to maintain the required power output. However, the Semi-free-piston version of the Stirling engine overcomes much of that problem by placing the two main parts of the engine in separate locations. This allows each to be built optimally and fit more neatly into the fish robot. The displacer piston and electrical motor can be placed near the heat source in a convenient part of the robot while the power piston can be located where needed to directly power the tail assembly linkages. Of course, we need to analyze the engine performance in carefully, because the separated cylinders invites larger dead volume and decreasing of engine power.

I think that this engine has a strong possibility to be the power source of choice for the fish robot although it has many problems yet to be resolved.

If you want more information of the Stirling engine, please connect to Stirling Engine Home Page. |

| Contact khirata@nmri.go.jp |

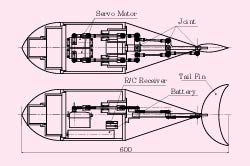

The figure to the right shows the structure of a Semi-free-piston Stirling engine that is the object of this study.

The figure to the right shows the structure of a Semi-free-piston Stirling engine that is the object of this study. In the past, an electric battery and electric motor have been used as the power source. Electric motors are highly controllable, but the problem is, that batteries do not allow for a long operation on a single charge. This is because electric batteries have low energy density, that is, they have a low Watt-Hour per Kilogram. On the other hand, if the Stirling engine can be used as the power source, it can use any source of heat; and there are any number of high density heat sources available, fossil fuels foremost among them. The Stirling engine has the potential for long un-refueled operation because of both high energy density fuel availability and the high efficiency potential of the Stirling engine itself.

In the past, an electric battery and electric motor have been used as the power source. Electric motors are highly controllable, but the problem is, that batteries do not allow for a long operation on a single charge. This is because electric batteries have low energy density, that is, they have a low Watt-Hour per Kilogram. On the other hand, if the Stirling engine can be used as the power source, it can use any source of heat; and there are any number of high density heat sources available, fossil fuels foremost among them. The Stirling engine has the potential for long un-refueled operation because of both high energy density fuel availability and the high efficiency potential of the Stirling engine itself.