|

| ||||||||

|

Let's Build a Model Stirling Engine Boat May 2001, by Koichi Hirata

|

|

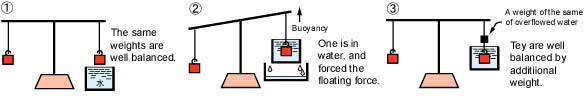

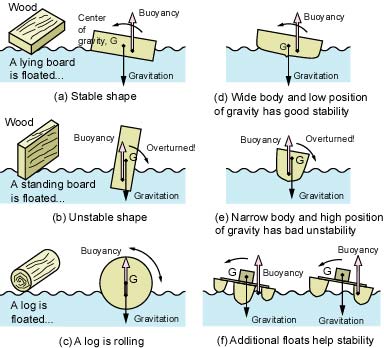

Point 2: Stable Body Shape without Overturn A flat wood board floats to lie on water. It cannot float to stand up on water. The floating board always sways by wind or waves. When the lying board leans somewhat, the board receives both a floating force (buoyancy) and the weight (gravitation) as shown in the figure to the right (a). So, the board receives a moment to keep the lying position. If the board is floated with standing up, the moment becomes to lying direction, and it overturns soon. Thus, in order to be stabilized and float the board material on water, the shape of a board and the center-of-gravity position is very important. When building a boat, you must consider the shape of the boat and the center-of-gravity position firmly.

|

Stability of a Boat

|

Even if a boat is stabilized and has floated, the shape like a flat board has a big drag force, then high-speed running cannot be desired. The drag force decreases with decreasing of the surface area between the hull and water. When boats have the same weight, the circular shape like the above figure (c) has smaller surface area than the squarish shape like (a) and (b). However, in considerations of the weight of a Stirling engine and its feature, it is difficult to keep the stability with the circular shape of the boat. Also, the drag force decreases with decreasing the waves which occured with the boat running. That is, the better boat has a pointed shape, smooth surface, no-bumpy in water, a slim and long body.

Examples of Stirling Engine Boats

Examples of Stirling Engine Boats

Here, several Stilring engine boats are introduced. The boat (a) of the following figure was developed to imagine of a high-speed boat such as a racing boat. It has the circular shape of sectional area, and a long hull. Such shape has low drag force, though it is bad unstable. A twin-hull type boat (b) and an outrigger boat have good stability. They are seldom capsized even if the center-of-gravity position is quite high. So, it can be said that they are suitable for the first prototype of Stirling engine boat. The boat (d) is a special boat called 'Half-Diving-type'. A lower pillar portion sinks in water. There are only thin stays through water surface, then the drag caused by the waves becomes small. However, adjustment of lift is very difficult.

You can also select the propulsive method. A screw propeller is used as that of the boat (a) and (c). The screw propeller is very efficient for push water. An air propeller is used as that of the boat (b) and (d). It is easy to adapt to the Stirling engine boat, but the propulsive force is lower than that of the screw propeller. As the other propulsive methods, the boat (e) uses water wheels , and the boat (f) uses a fish-like swimming mechanism.

The hull has the circular shape and slim. Low drag and bad stability. MPEG Movie (1 MB) |

This has two hulls and good stability. It does not overturn though it has high center-of-gravity position. MPEG Movie (1 MB) |

This has additional floats both sides and good stability. It does not overturn though it has high center-of-gravity position. MPEG Movie (1 MB) |

A lower pillar portion sinks in water. Adjustment of lift is difficult although drag is small. |

The amphibious boat which attached the water wheel beside the hull. MPEG Movie (1.1 MB) |

The model boat which runs while shaking the tail fin at right and left like a fish. MPEG Movie (1.2 MB) |

Stirling Engine for a Boat

Stirling Engine for a Boat

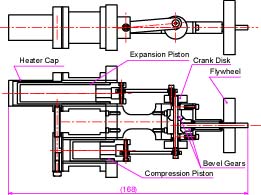

The Stirling engine for a boat must be both light weight and high power. In a consideration of the stability of the boat, it is better selection to have lower position of the center-of-gravity.

The Stirling engine for a boat must be both light weight and high power. In a consideration of the stability of the boat, it is better selection to have lower position of the center-of-gravity.

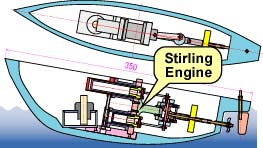

The figure to the right shows an Alpha-type Stilring engine, which was designed to use a model boat. It has bore of 15 mm and stroke of 6 mm. The glass syringes are used as the pistons and cylinders. In order to get the lower center-of-gravity position, the engine is set with lying. To drive a screw propeller, the direction of the output shaft is changed by bevel gears.

Assewmbling plan of the MSE-05 (Autodesk DWF format)

Assewmbling plan of the MSE-05 (Autodesk DWF format)

Parts plans of the MSE-05, No.1-3 (Autodesk DWF format)

Parts plans of the MSE-05, No.1-3 (Autodesk DWF format)

Parts plans of the MSE-05, No.4-5 (Autodesk DWF format)

Parts plans of the MSE-05, No.4-5 (Autodesk DWF format)

Parts plans of the MSE-05, No.6-8 (Autodesk DWF format)

Parts plans of the MSE-05, No.6-8 (Autodesk DWF format)

Parts plans of the MSE-05, No.9-10 (Autodesk DWF format)

Parts plans of the MSE-05, No.9-10 (Autodesk DWF format)

Parts plans of the MSE-05, No.11-12 (Autodesk DWF format)

Parts plans of the MSE-05, No.11-12 (Autodesk DWF format)

Parts plans of the MSE-05, No.13-17 (Autodesk DWF format)

Parts plans of the MSE-05, No.13-17 (Autodesk DWF format)

Parts plans of the MSE-05, No.18-22 (Autodesk DWF format)

Parts plans of the MSE-05, No.18-22 (Autodesk DWF format)

Additional plans of the MSE-05, No.A1-A3 (Autodesk DWF format)

Additional plans of the MSE-05, No.A1-A3 (Autodesk DWF format)

Download of the whole CAD data including the hull and the engine (Autodesk AutoCAD 2000 DWG format)

Download of the whole CAD data including the hull and the engine (Autodesk AutoCAD 2000 DWG format)

Download of the whole CAD data including the hull and the engine (Autodesk AutoCAD 2000 DXF format)

Download of the whole CAD data including the hull and the engine (Autodesk AutoCAD 2000 DXF format)

- * WHIP! allows you to distribute CAD (DWF format) files over a network without AutoCAD software. It is available for download free of charge at the web site of Autodesk, Inc.

- * Above plans are drawn for my manufacturing only.

- * Please note that the CAD data includes Japanese fonts and characters, they may not show correctly on your PC.

- * Above plans are drawn for my manufacturing only.

How to Build a Hull

How to Build a Hull

There are many ways for building of a hull, such as using frame of square lumbers or using F.R.P. Here, we build the hull using piled up boards of balsa. This can be built easily, and can stop the water leakage easily. Structure of the boat for building (Autodesk DWF format)

Structure of the boat for building (Autodesk DWF format) Paper pattern of the hull (Autodesk DWF format)

Paper pattern of the hull (Autodesk DWF format) Additional parts of the boat, No.B1〜B6(Autodesk DWF format)

Additional parts of the boat, No.B1〜B6(Autodesk DWF format) Download of the whole CAD data including the hull and the engine (Autodesk AutoCAD 2000 DWG format)

Download of the whole CAD data including the hull and the engine (Autodesk AutoCAD 2000 DWG format) Download of the whole CAD data including the hull and the engine (Autodesk AutoCAD 2000 DXF format)

Download of the whole CAD data including the hull and the engine (Autodesk AutoCAD 2000 DXF format)- * WHIP! allows you to distribute CAD (DWF format) files over a network without AutoCAD software. It is available for download free of charge at the web site of Autodesk, Inc.

- * Above plans are drawn for my manufacturing only.

- * Please note that the CAD data includes Japanese fonts and characters, they may not show correctly on your PC.

- * Above plans are drawn for my manufacturing only.

Conclusion

Conclusion

After the Stirling engine boat is completed, run the engine, and float it on water. Also let us adjust the size or pitch of the screw propeller, then try to get high-speed running. Our boat could run at about 0.6 m/s lightly.

After the Stirling engine boat is completed, run the engine, and float it on water. Also let us adjust the size or pitch of the screw propeller, then try to get high-speed running. Our boat could run at about 0.6 m/s lightly.Tips of the development of a high-speed Stirling engine boat are that the development of a low drag hull and high-power engine. Also the engine and the hull are reqired light weight. A running boat on water is very beautiful. Please try to develop a high-speed Stirling engine boat.

Please note that the balsa burns well. The engine must be heated near water.

MPEG Movie of the Model Boat (2 MB)

MPEG Movie of the Model Boat (2 MB)

[ Stirling Engine Dictionary ]

A model Stirling engine has a simple structure. So, you can build one

easily. Several model cars powered by the Stirling engine have been built

in Japanese high-schools and universities. Of course, you can also build

a model boat powered by the Stirling engine. You may think that building

of the boat is very easier than that of the car, because the boat has fewer

drive mechanisms. Yes, it is easy to float the boat on the water. However,

it is not easy to develop a high-speed boat. Because the water drag of

the boat is very bigger than the air drag of the car. There are several

points for the development of the Stirling engine boat. Let's study the

points and build the model boat.

A model Stirling engine has a simple structure. So, you can build one

easily. Several model cars powered by the Stirling engine have been built

in Japanese high-schools and universities. Of course, you can also build

a model boat powered by the Stirling engine. You may think that building

of the boat is very easier than that of the car, because the boat has fewer

drive mechanisms. Yes, it is easy to float the boat on the water. However,

it is not easy to develop a high-speed boat. Because the water drag of

the boat is very bigger than the air drag of the car. There are several

points for the development of the Stirling engine boat. Let's study the

points and build the model boat.