Structure of heat exchangers

The feature of the heat exchanger system is shown in following figures. The specifications of the heat exchanger system are determined as shown in following table.

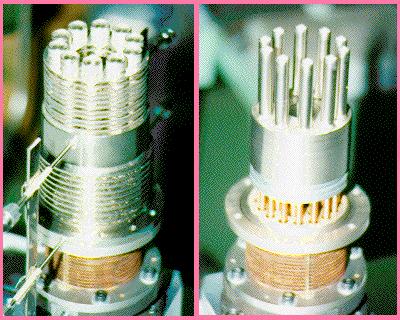

Heater

Heater

The heater tube number is determined to be ten to provide enough heat transfer area and to keep the heater outer-boundary within the cylinder diameter. In order to decide the detail size of the heater, a heat transfer performance of the heater was calculated individually. The prototype engine has the specialized heat exchanger system. The reciprocated inner tubes at the top of the displacer is not allowed to touch outer tubes absolutely. In order to increase the performance of the heat transfer, it is effective method that decreasing a clearance between the inner tube and the outer tube but the clearance has a limit because there are deformation of the heater tubes by heating and twisting. After the discussion about these problems, the clearance was decided 1.45 mm.

On the outside of the heater, eleven fins are attached to each heater tubes with a 1.5 mm thickness as shown in above figure. The fins play a role of increasing the heat transfer and preventing the deformation of outer heater tubes.

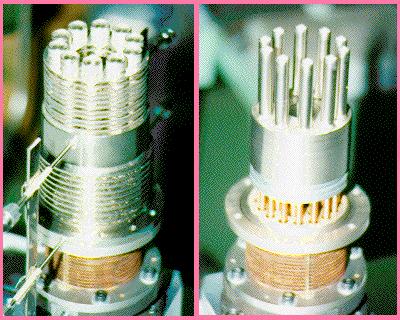

Regenerator

Regenerator

A regenerator is built in the displacer piston. The regenerator adopted two different type matrix. One is conventional piled mesh made of stainless steel. Another is a porous type matrix which is pressed zigzag stainless steel wires called "mesh spring". The latter matrix is not well known about its performance. Measuring its characteristics will be a subject of next step. It is expected as a matrix of practical use Stirling engine because the matrix can be made in low cost and has a good assembling performance.

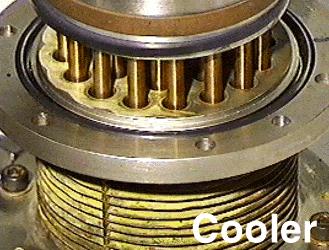

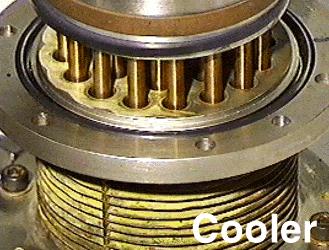

Cooler

Cooler

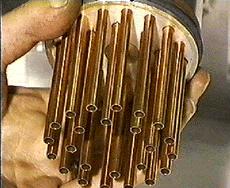

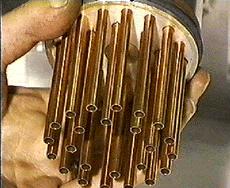

In the case of the engine used for the portable generator, its cooling system is suited to air cooling system. The prototype of the cooler is designed as using air cooling. It has twenty-four tubes made of copper and air flow along the outer tubes. The detail size of the cooler is decided by the heat transfer calculation. For the material, copper is used for soldering. In the case of the first experiment, the engine will be used water cooling system because the compression space temperature will be demanded to be constant. A water jacket covers outside of the cooler.

|

Heater

Heater