Research Overview

Research Overview

Research on Fundamental Techniques for Deep-sea Mineral Resource Development

Research on Seabed Mineral Resource Development

Japan's Exclusive Economic Zone contains many mineral resources, such as seafloor hydrothermal deposits(*1), cobalt-rich crusts, and manganese nodules. Therefore, research and development of mining systems for these resources are being carried out as a national project. However, many technical challenges need to be resolved in the development and operation of these mining systems.

The Deep Sea Technology Research Group is conducting research on the following four themes to contribute to the development of seabed mineral resources:

- Research on Elemental Technologies for Excavating Seabed Mineral Resources

- Research on Elemental Technologies for Lifting Seabed Mineral Resources(*2)

- Research on Processing Seabed Mineral Resources on the Seafloor

- Research on the Operability, Safety, and Economic Aspects of Seabed Mineral Resource Development

Here, we introduce our research on the evaluation of lifting pipes(*3)and flexible hose(*4), which is part of our study on the elemental technologies for lifting seabed mineral resources.

Evaluations of internal flows by air-lift pumping systems

One method for excavating subsea minerals is air-lift pumping system. In this system, internal flow in pipes is gas?liquid?solid three-phase flow. Therefore, flow assurance for three-phase flow is essential for designing and operating the system. Our group conducted experiments on three-phase flows to obtain data for establishing the evaluation model (Figure 1 and 2) and simulated the internal three-phase flows. Our group showed the constitutive equations for gas and solid velocities and simulated using them. We also validated the simulation results by comparing experimental data (Figure 3).

- Submarine hydrothermal deposits: Seawater that has penetrated deep into the seabed is heated by magma, extracting elements contained in the crust, and is ejected as hot water from the seabed into the ocean. During the cooling process, minerals containing heavy metals such as copper, lead, zinc, gold, and silver precipitate.

- Lift: transferring ores excavated from the seabed to the surface.

- Lifting Pipes: pipes used to convey the ore excavated from the seabed to the surface.

- Flexible hose: pipes for connecting a subsea production tool to a suspended submergible slurry pump.

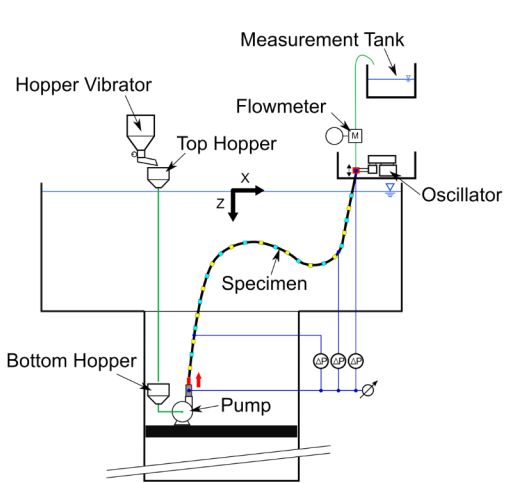

Figure 1 Schematic of the experimental apparatus

Figure 2 Example of experimental results (relation between mixture superficial velocities and gas velocities)

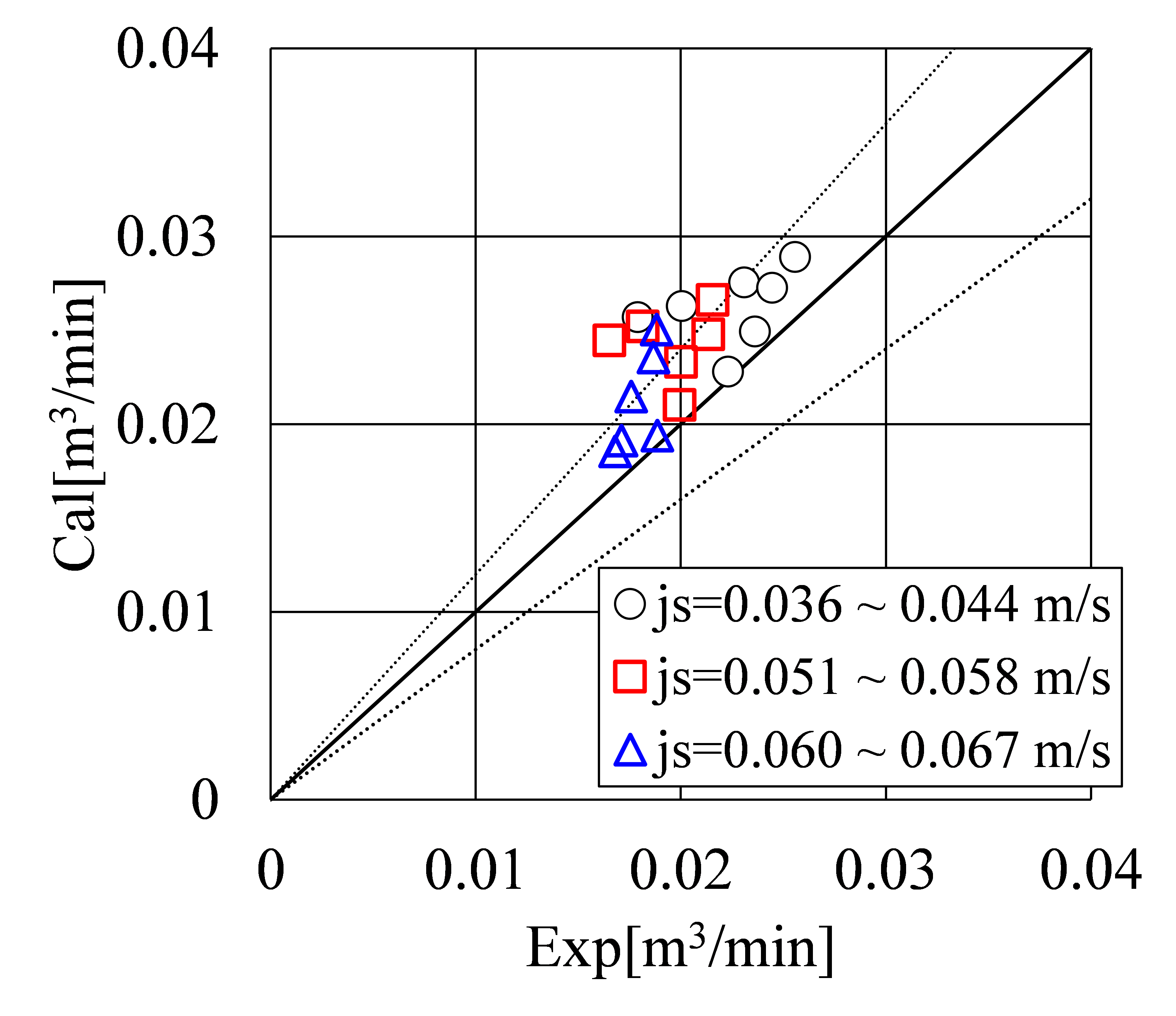

Figure 3 Comparison of simulated results and experimental results (liquid flow rates)

Reference

- Takano, S. and Masanobu, S., Effect of internal diameter of pipe on velocity distribution for gas–liquid–solid three-phase pipe flows, Proceedings of the ASME 2025 44th International Conference on Ocean, Offshore and Arctic Engineering, OMAE2025, June 22-27, 2025, Vancouver Columbia, Canada.

- Takano, S. and Masanobu, S., Numerical simulation on gas–liquid–solid three–phase flow by gas–lift pumping system for deep sea mining, Proceedings of the ASME 2023 42nd International Conference on Ocean, Offshore and Arctic Engineering, OMAE2023, June 11-16, 2023, Melbourne, Australia.

- Takano, S., et al., Experimental study on void fractions and pressure drops in three-phase flow for deep sea mining, Proceedings of the ASME 2021 40th International Conference on Ocean, Offshore and Arctic Engineering, OMAE2021, June 21-30, 2021, Virtual, Online.

Motion of flexible hose

The systems for excavating subsea minerals are assumed to have the flexible hose connecting subsea production tool, which excavates minerals on the seafloor, to submergible slurry pump, which conveys ore to the sea surface. Estimating the configuration and dynamic motion of flexible hose is essential for designing and operating the systems. Our group conducted a model-scale experiment (Figure 4) to establish the method for estimating the configurations and the motions. The experimental results showed the solid volume fraction had an influence on the static configuration (Figure 5). In addition, our group developed the simulation program to calculate the configurations and motions of flexible hose. The simulation with a density distribution showed better agreement with the experimental mode shape than the simulation with a homogeneous flow (Figure 6).

Figure 4 Schematic of the experimental apparatus

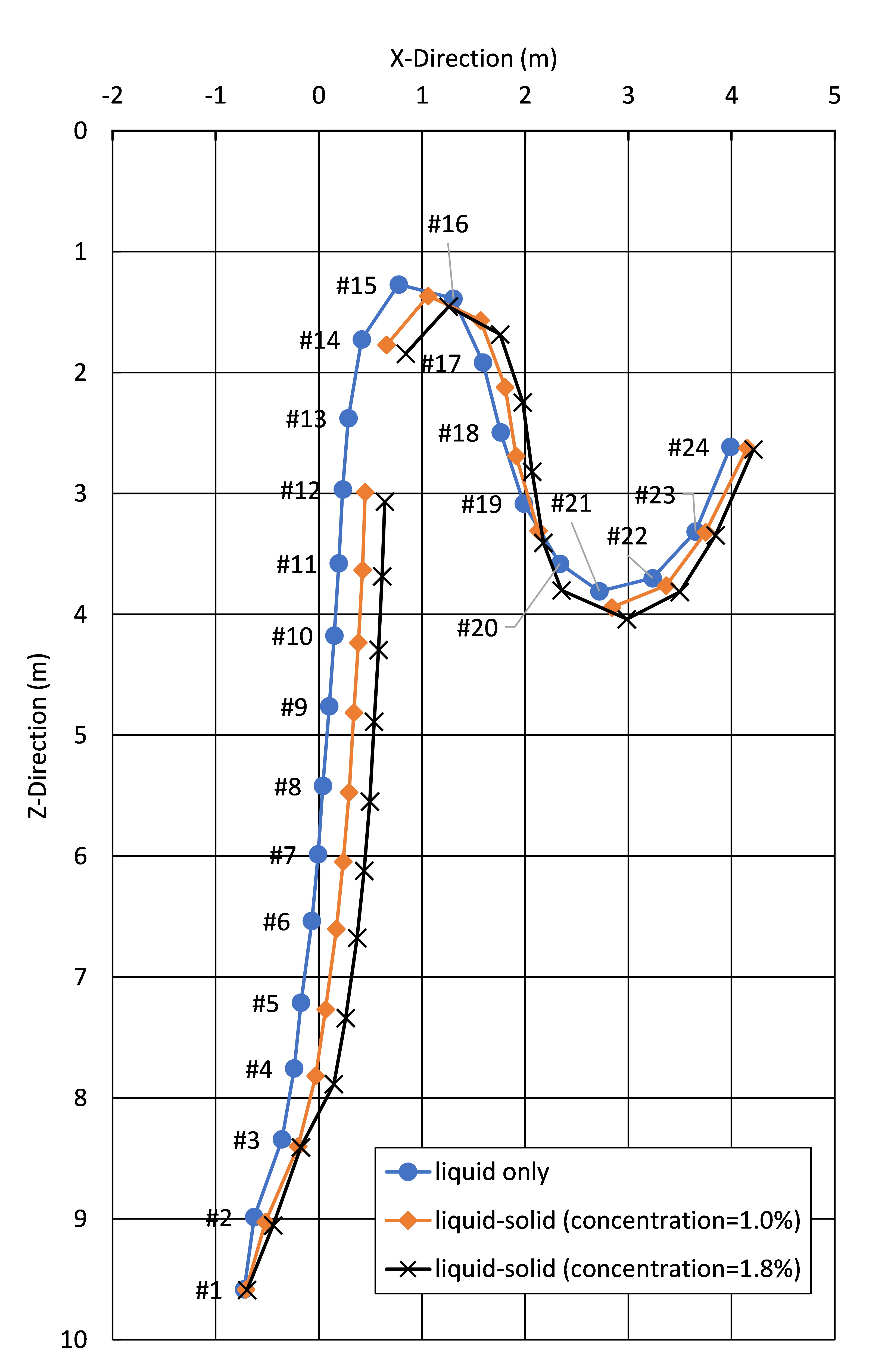

Figure 5 Comparison of configuration of model scaled pipe

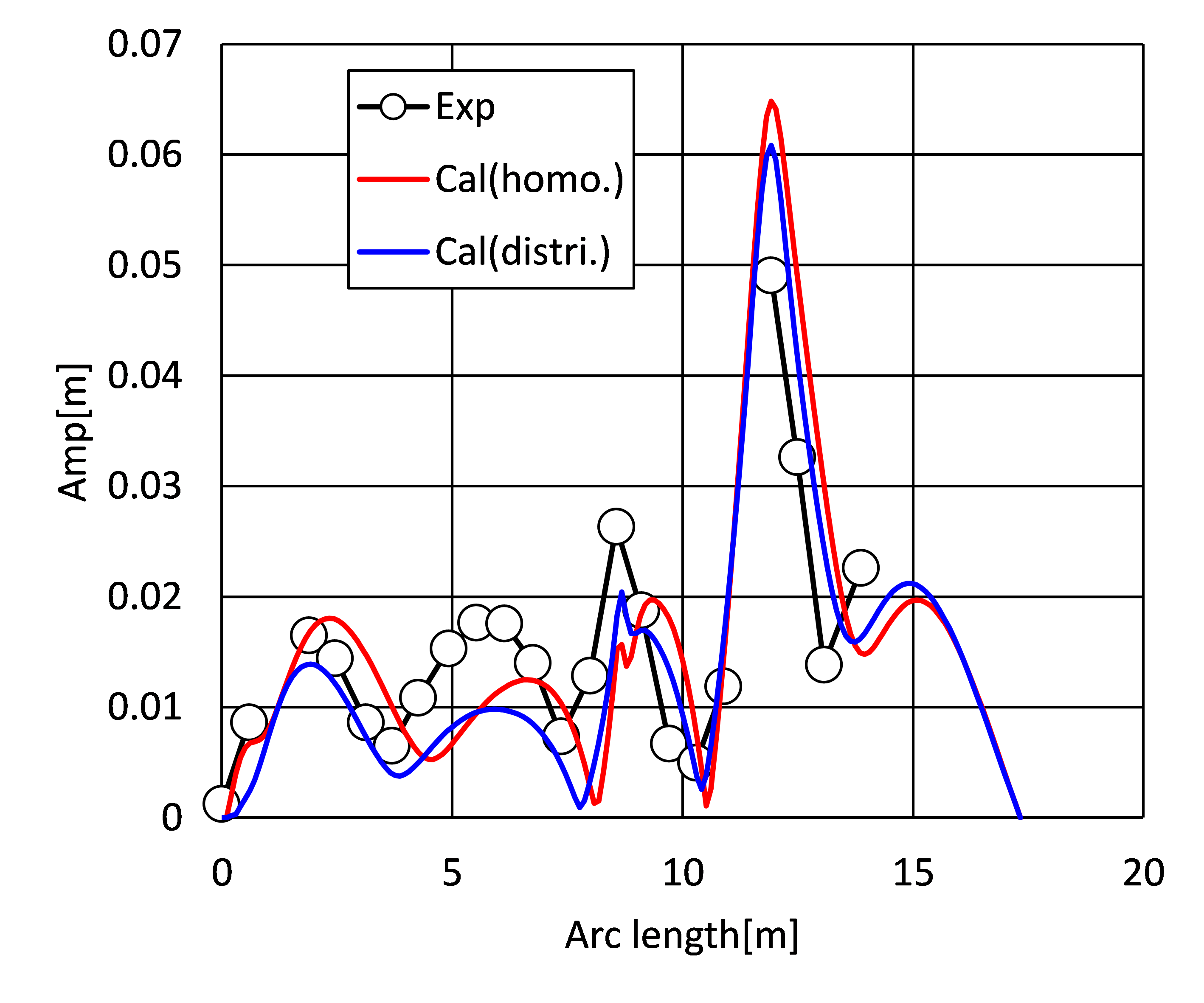

Figure 6 Calculated results of motions of model scaled pipe

Reference

- Takano, S. and Masanobu, S., Effect of axial density distribution in liquid–solid flow in pipes on the jumper for deep sea mining, Proceedings of the ASME 2024 43rd International Conference on Ocean, Offshore and Arctic Engineering, OMAE2024, June 9-14, 2024, Singapore EXPO, Singapore.

- Yamamoto, M., et al., Numerical simulation of a jumper conveying slurry for deep-sea mining, Proceedings of the ASME 2021 40th International Conference on Ocean, Offshore and Arctic Engineering, OMAE2021, June 21-30, 2021, Virtual, Online.

- Yamamoto, M., et al., The effects of solid-liquid internal flow on the dynamic behavior of a reduced scale jumper for deep-sea mining, Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering, OMAE2020, June 28-July 3, 2020, Fort Lauderdale, FL USA.