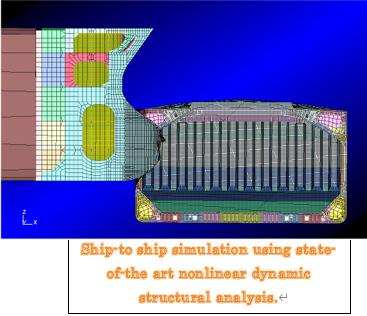

Ship-to-ship collision simulations

using a state-of-the-art non-linear CAE Technology

SHIP-TO-SHIP COLLISION SIMULATIONS USING A STATE-OF-THE-ART NON-LINEAR CAE TECHNOLOGY

-

NMRI could provide the following simulation technologies using state-of-the-art non-linear CAE technology.

These simulation technologies are utilized in various projects to provide solutions.- Ship-to-ship collision simulation

- Hull girder ultimate strengthanalysis

- Fluid-structure interaction (FSI) analysis

-

Nonlinear FEM

In NMRI, general-purpose non-linear structural analysis software “LS-DYNA (LSTC, USA)” is usually utilized to carry out ship-to-ship collision simulations. This software is widely used in various industries, including car and airplane industries. This software is a de facto standard software in collision and grounding analysis of ships. In collision simulation, time-domain analysis is carried out and by using time-domain analysis after the contact of two ships, phenomena of buckling, collapse, and failure are well simulated. This software also provides multi-physics analysis, including fluid-structure coupling as welll as heat-structure coupling.

What is non-linear ?

- Material Non-linearity ( Material constitutive model, nonlinear relation between stress and strain )

- Geometric Non-linearity ( Large deformation, infinite deformation )

- Boundary Non-linearity ( Contact, static or dynamic friction )

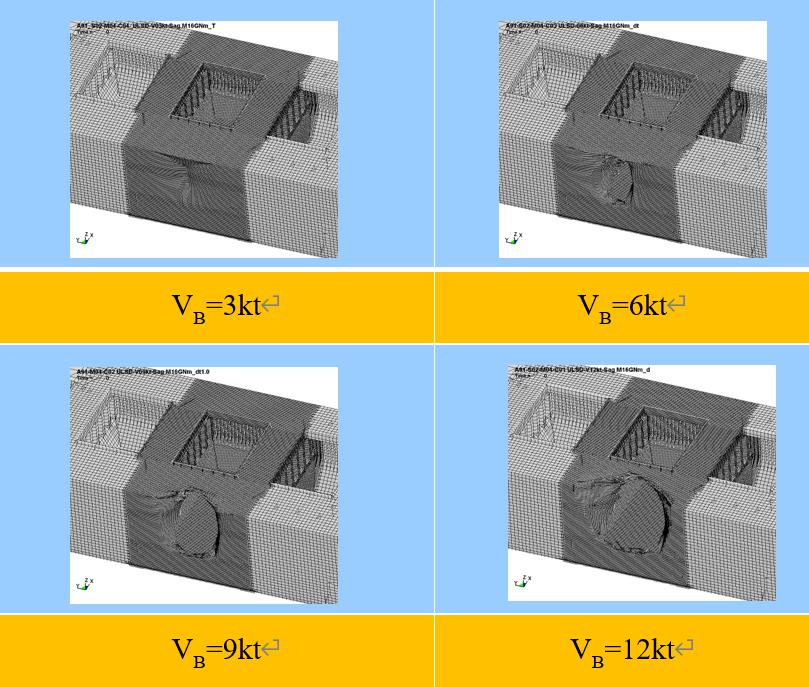

【ship-to-ship collision simulation】

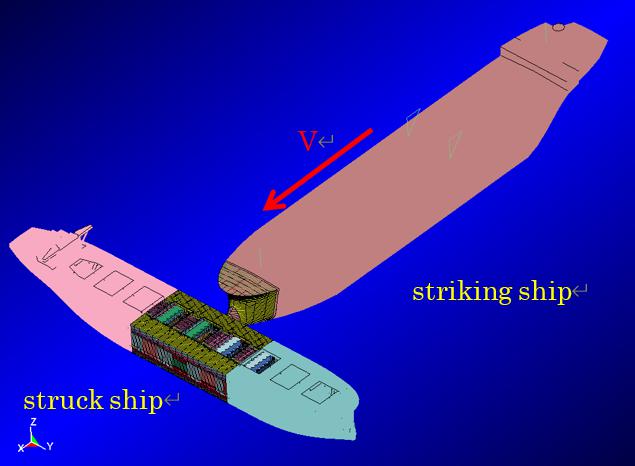

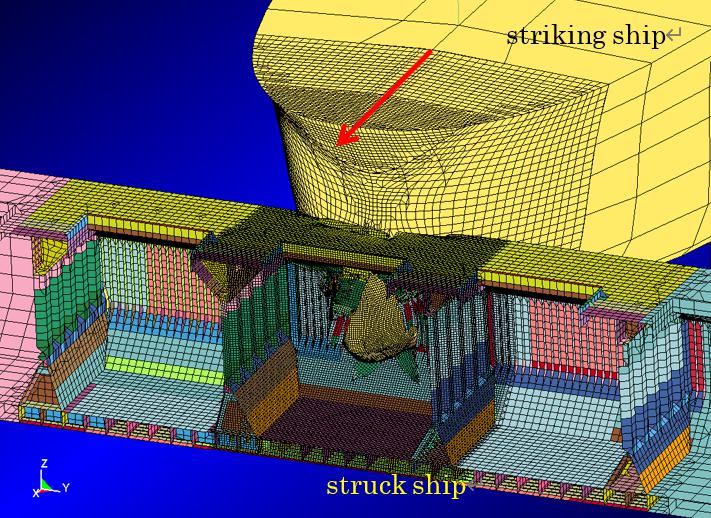

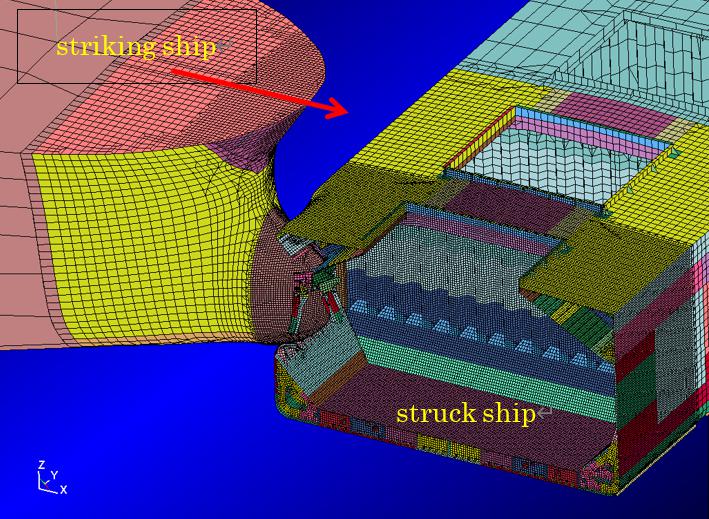

- Collision and grounding are the primary causes of maritime accidents. Therefore, from the view point of safety of life and the maritime environment, it is important to keep sufficient structural strength to prevent disastrous consequences such as ship breaking and sinking.

- It is difficult and impractical to evaluate the crashworthiness of ships using real ships due to their large structures. Instead, the crashworthiness of ships is usually evaluated by advanced large-scale numerical simulations.

- NMRI provides ship-to-ship numerical simulations considering ship motions, added mass effects, restoring force (Roll, Pitch), failure of the material, strain-rate dependency, contact between structural members, friction (static/dynamic) where six degrees of freedom is set on the center of gravity of the ship. As a material constitutive model, the relation between effective-plastic strain and effective stress needs to be defined. Failure strain is used as one of the failure criteria, but it depends on the element sizes and effect of stress-axiality, and various know-how is needed.

【References】

- Yamada, Y., Endo, H., Pedersen, P.T., "Collapse Strength of the Bulbous Bow Structure in Oblique Collision," Proceedings of International Conference of Collision and Groundings of Ships (ICCGS-2004), pp.160-171, (2004)

- Yamada, Y., Endo, H., Kawano, H, "Collapse Mechanism of the Buffer Bow Structure on Axial Crushing," International Journal of Offshore and Polar Engineering (IJOPE), Vol. 15, No. 2, pp. 147-154, (2005)

- Yamada, Y., Endo, H., Pedersen, P.T., "Numerical Study on the Effect of Buffer Bow Structure in Ship-Ship Collision," Proceedings of The Fifteenth International Offshore and Polar Engineering Conference (ISOPE-2005), pp.604-611, (2005)

- Yamada, Y., Pedersen, P.T., "Simplified Analysis Tool for Ship-Ship Collision," Proceedings of The Seventeenth International Society of Offshore and Polar Engineering Conference (ISOPE-2007), pp.3760-3767, (2007)

- Yamada, Y., Pedersen, P.T., Friis-Hansen, P., "The Effect of Buffer Bow Structures on Probabilistic Collision Damages of Oil Tankers," Proceedings of International Conference of Collision and Groundings of Ships (ICCGS-2007), pp.235-242, (2007)

- Yamada, Y., Pedersen, P.T., Friis-Hansen, P., "Risk Reducing Effect of Buffer Bow Structures on the Collision Damage of Oil Tankers," Risk Workshop at Technical University of Denmark, (2007)

- Yamada, Y., Endo, H., "Experimental and Numerical Study on the Collapse Strength of the Bulbous Bow Structure in Oblique Collision," Marine Technology, Vol.45, No.1, pp.42-53, (2008)

- Yamada, Y., Endo, H., Pedersen, P.T., "Effect of Buffer Bow Structure in Ship-Ship Collision," International Journal of Offshore and Polar Engineering (IJOPE), Vol.18, No.2, pp.133-141, (2008)

- Yamada, Y., Pedersen, P.T., "A Benchmark Study of Procedures for Analysis of Axial Crushing of Bulbous Bows," Marine Structure, Vol.21, pp.257-293, (2008)

- Yamada, Y., Ogawa, Y., "Study on the residual ultimate longitudinal strength of hull girder of a bulk carrier against a sagging moment after ship collision," Advances in Marine Structures - Guedes Soares & Fricke(eds), pp.429-436, (2011)