Fluid Control Research Group

FLUID CONTROL

For the development of eco-friendly and energy-saving ships, this group is engaged in research and development of advanced technologies for computational fluid dynamics (CFD) applications and tank testing and is developing fundamental ship design tools based on the results of these studies. Furthermore, by applying the results of basic research, this group is developing hull forms, propellers, and energy-saving devices that are more closely aligned with its products and embodying new energy-saving concepts to meet the needs of its customers (ship owners, shipyards, etc.) through collaborative or contracted research projects.

Fluid Control Research Group Logo

Members

(◎: Head of the Group)

Mission

- Development of zero GHG emission ships.

- Advancement of the air lubrication system, elucidation of the skin-friction reduction mechanism, and creation of the new energy-saving concept based on its principle.

- Advancement of energy-saving devices to improve propulsive performance.

- Development of predictive technology for underwater noise emission from ships and low noise and high efficiency propellers.

- Development of optical measurement technology for interfering flow field around hull, propeller, and cavitation.

Overview of Research

1. Skin-friction drag reduction and its evaluation methods

Skin-friction drag reduction measurements by air lubrication method

using 36m length flat plate model at high reynolds number (Towing speed 8 m/s)

Skin-friction measurements of hull coating using 14m length flat plate

(Towing speed 4 m/s)

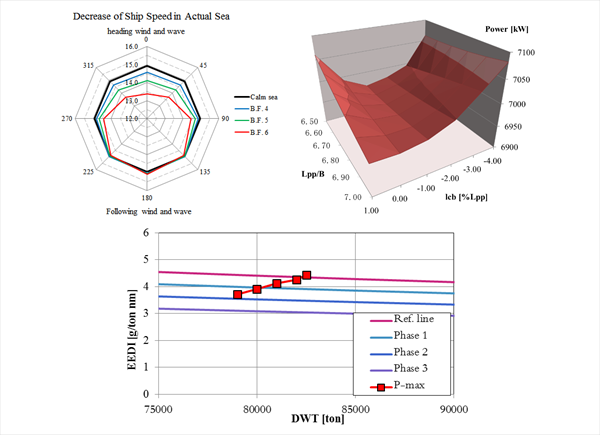

2. Design of High Energy Efficiency Ship

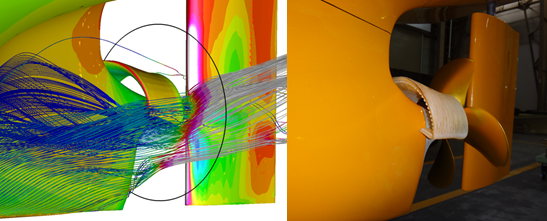

The maritime industry is making significant efforts to alleviate the global warming issue, ex. Since 2013, a regulation of the Energy-Efficiency Design Index was introduced to address the issue. For this reason, the development of environmentally friendly ships plays an essential role in solving the issue. Our group is developing eco-friendly ships and energy-saving devices by applying a detailed analysis of the flow around the hull using computational fluid dynamics (CFD) and a highly efficient water tank test method.

EEDI certification test (ISO 9001 certified) (left)

and the energy-saving device WAD installed on a ship (right)

Results of CFD analysis of the energy-saving device USTD (left)

and a model made with a 3D printer (right)

Actual vessel with an energy-saving hull form that reduces CO2 emissions by more than 16% compared to conventional vessels

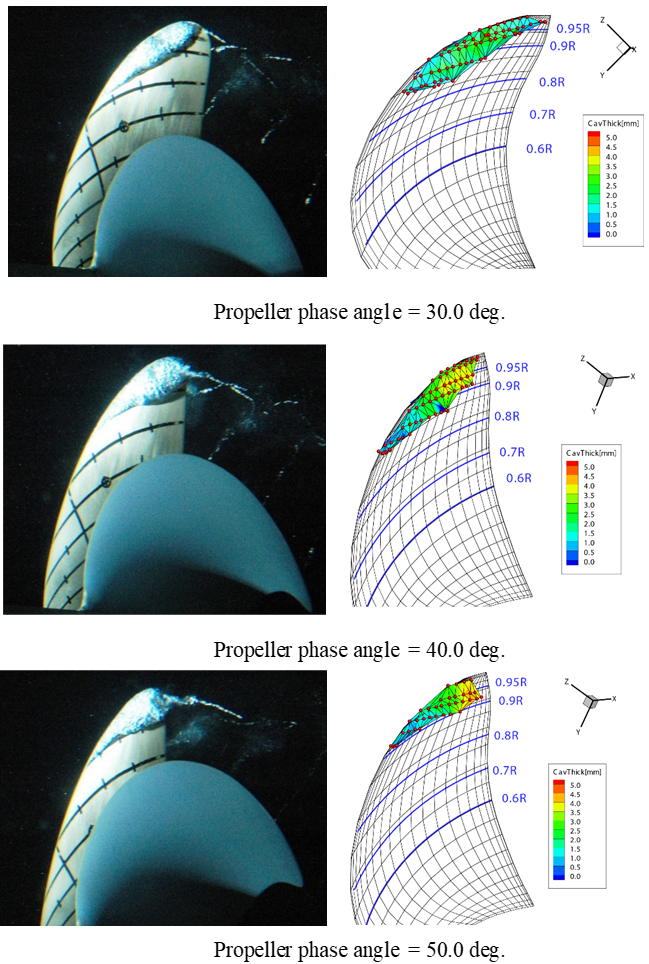

3. Propeller Cavitation

In recent years, demands for lower hull vibration and noise of ships have been increasing. The primary causes of the hull vibration are engine and propeller cavitation. A high-accuracy estimation method of the pressure fluctuation caused by cavitation is required. It is crucial for the estimation method to accurately calculate the second-order time variation of the cavity volume of the unsteady cavitation on the propeller blade. However, current theoretical prediction methods are not accurate enough, and verification of theoretical prediction methods using the results of cavity shape measurements is essential to improve accuracy further. Our group has developed a 3D shape measurement system using a combination line CCD camera method. This system enables fast and accurate shape measurement underwater. Our group has been developing a measurement method for the cavity shapes on a propeller blade using the developed 3D shape measurement system. This system can measure the cavity shapes that have been difficult to measure with high accuracy and resolution. In addition, the high-precision cavity shape measurement data obtained by our measurement system can contribute to the validation of the theoretical estimation method of the pressure fluctuation induced by cavitation.

Combination line CCD camera method

Cavitation volume measured by Combination line CCD camera method

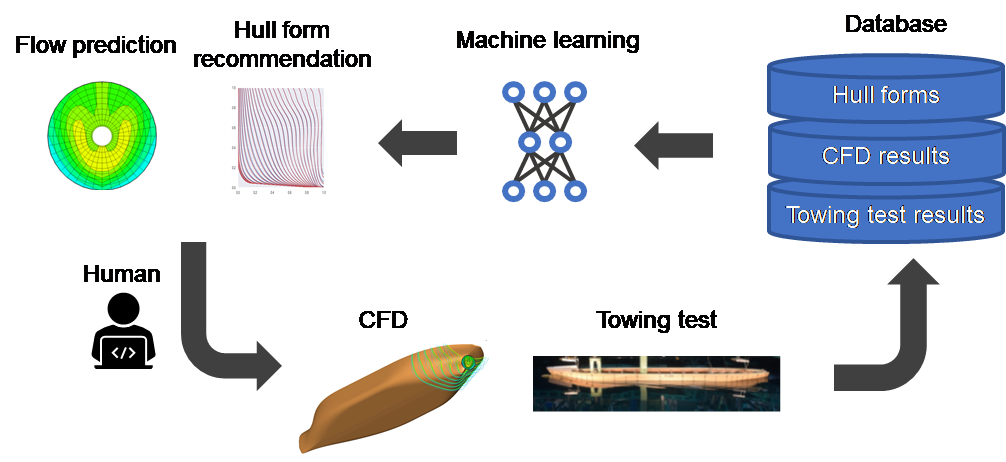

4. Development of a novel ship design method utilizing AI technology

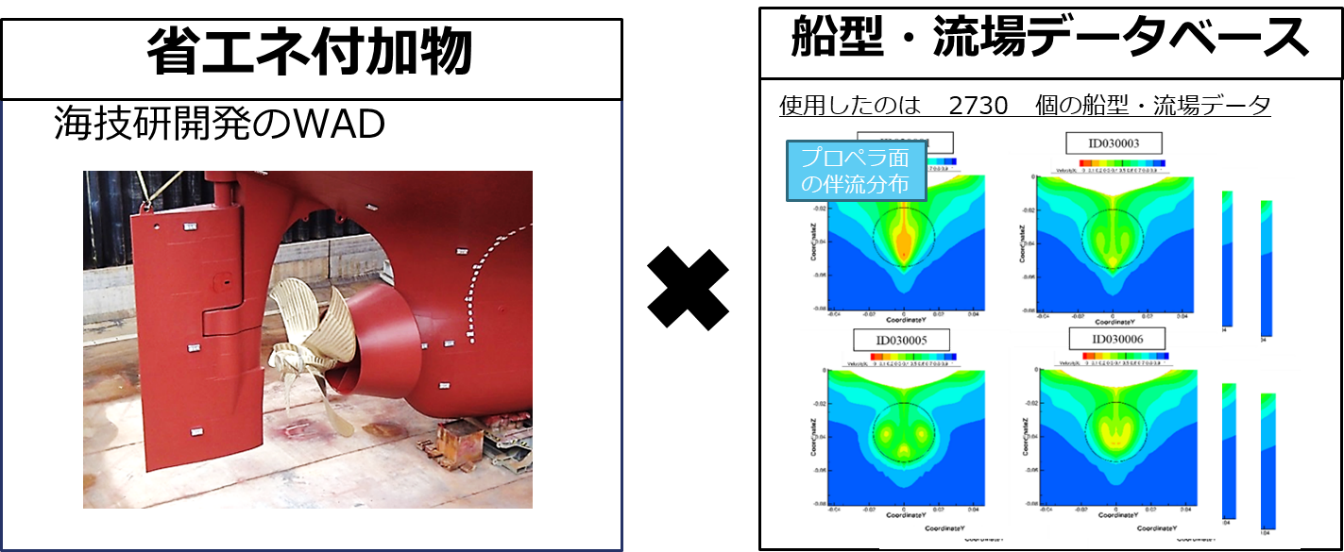

Our group is building a hull form and flow field database and developing a novel ship design method utilizing AI technology.

Conceptual diagram of a new ship design method using AI technology

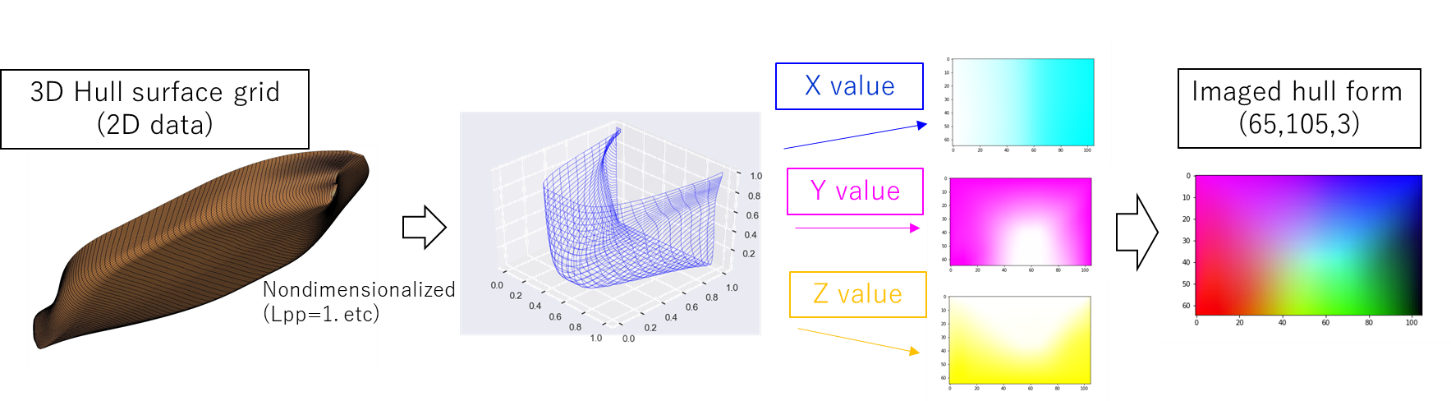

Implementing AI technology in hull form design necessitates the development of hull form representation methods tailored for AI use, capable of accurately representing complex 3D curved surfaces. Our group has been developing an image-based Curved Surface Representation (ICSR) to apply image recognition technology to hull design and has been promoting the application of AI technology to hull design.

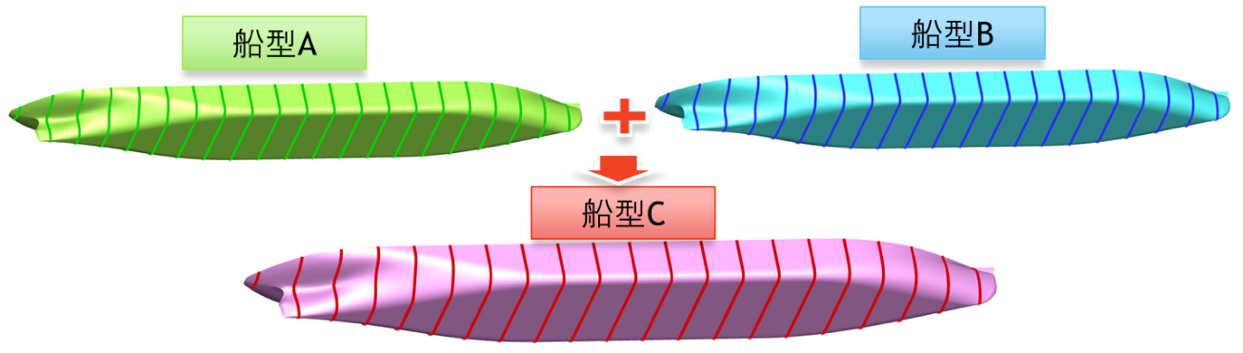

The database construction method is one of the key technologies to apply AI technology to ship design. Our group is developing a database construction method by utilizing a hull form blending (morphing) method, which can generate new hull forms automatically while retaining the genes of excellent hull shapes that are difficult to parameterize.

Conceptual diagram of a hull form blending

The hull form design has been developed based on the experience of expert engineers, and the transfer of these skills has been a challenge. Our research group has been studying to visualize the relationship between hull form and stern flow field, which has been known tacitly by experienced engineers, by utilizing the hull form database.

Visualization of changes in stern flow field due to ship shape change

(formal knowledge of tacit knowledge)

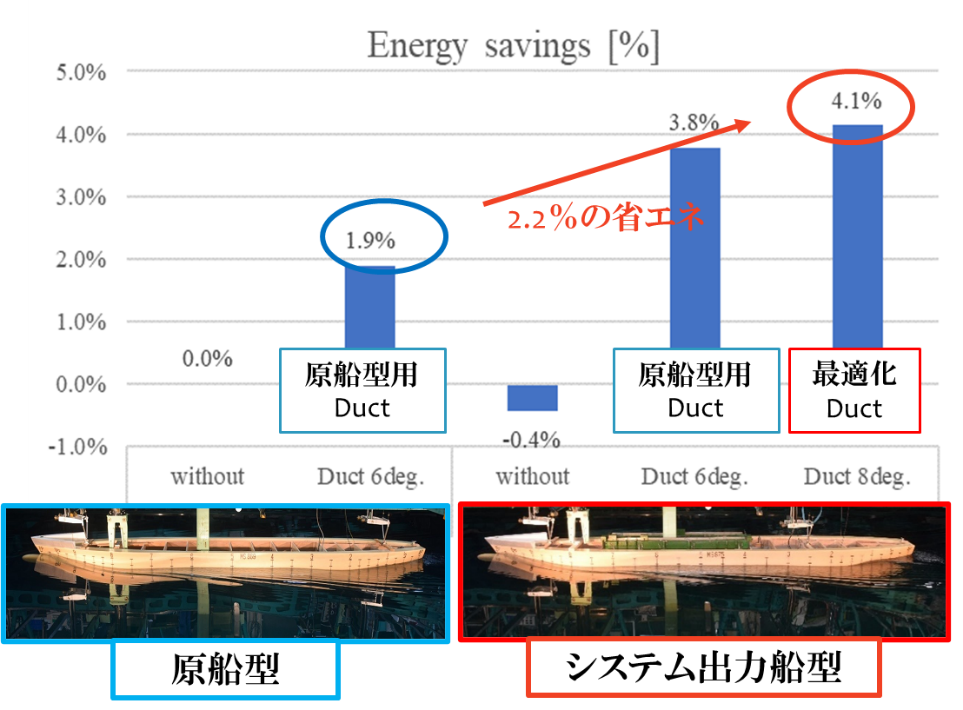

An example of a new hull form design method using AI technology is to develop an optimal hull form for energy-saving additives using the Wake Design System. In this example, we have developed a system that automatically guides the interference design between the hull form and the energy-saving device from the database, which has been done through trial and error by skilled engineers. As a result of tank tests, it was confirmed that the hull form output from the system is more effective for energy-saving devices, and is 2.2% more effective than the initial hull shape.

Energy saving effect of hull form suitable for energy saving duct designed by wake design system

HOPE Light, a hull form optimization program, is one of the systems widely used by shipyards and shipping companies to analyze the database in Japan. It can evaluate a ship's propulsive performance from the main dimensions of a vessel based on the database of tank tests conducted by NMRI. It can be used in practical applications such as initial hull form studies.

Click here for detailed instructions

Click here for detailed instructions

Sample of HOPE Light Output

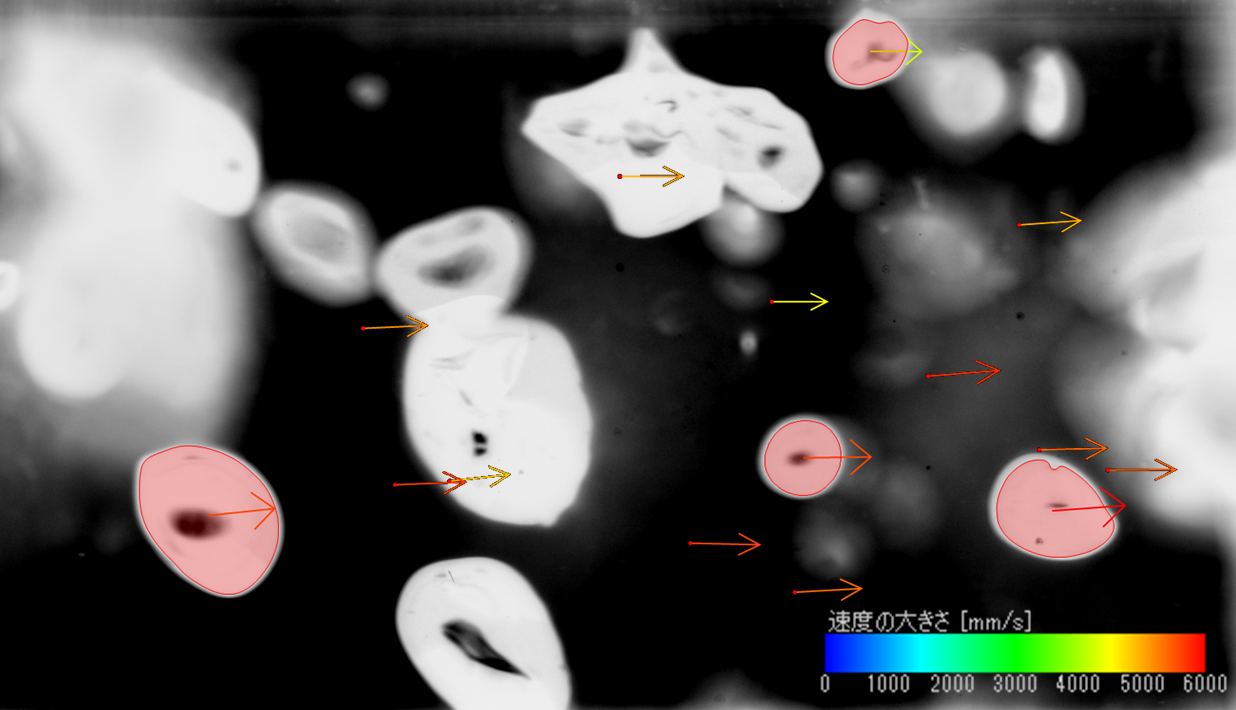

5. Flow filed measurements

To clarify complicated fluid phenomena such as gas-liquid two-phase flow and high Reynolds number flow around a real ship, we are developing advanced flow field measurement technology applying visualization technology such as laser.

Two-phase flow filed measurements using Particle Tracking Velocimetry and Shadowgprahy

Hull pressure fluctuation measurements in wave by Fiber Bragg Gating pressure sensor

Flow field measurements around model ship stern

by Underwater Stereo Particle Image Velocimetry system

Measured flow field and pressure distribution around ship stern

by Stereo PIV and FBG sensor

PIV measurements around energy saving device of actual ship

(Collaborate with KED Photonics (Germany) )