Power and Energy System Research & Development Group

POWER AND ENERGY SYSTEM

Members

(◎: Head of the Group)

Research Subjects

Biofuel Utilization

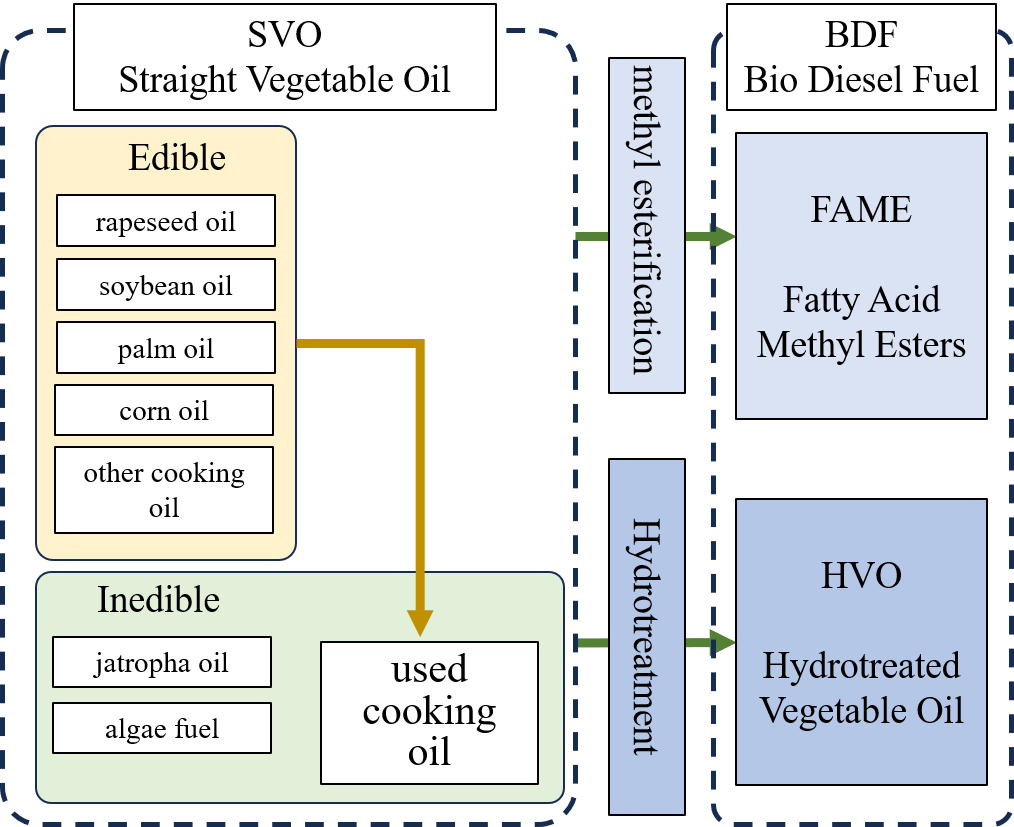

Biofuels are derived from vegetable oils, animal fats, and used cooking oils, and among other sources, and are considered to be carbon-neutral*. Generally, biofuels have similar characteristics to conventional marine fuels such as diesel and heavy fuel oil. Compared to other low- and zero-carbon fuels, such as methane, methanol, hydrogen, and ammonia, biofuels have been gaining attention as a method for reducing CO2 emissions, due to their seamless integration into existing engines and infrastructure.

Research has been conducted to investigate the physical properties, stability, and combustibility of various types of biofuels.

Physical properties: The temperature dependence of kinematic viscosity and density of biofuels and blended fuels with heavy fuel oil has been measured to determine the optimal temperature conditions for engine use.

Stability test: Blend stability tests has been conducted on biofuel-heavy fuel oil mixtures, along with oxidation stability test to assess the stability and shelf life of biofuels.

Combustion test: In addition to the ignition test of biofuels, large-scale engines are utilized to investigate change in fuel consumption and exhaust gas composition when biofuels are used.

*

Plants, the raw materials for biofuel, absorb CO2 from the atmosphere as they grow. This absorbed CO2 offsets the CO2 emitted when the biofuel is burned.

Types of biofuels

Hydrogen Fuel Utilization

Hydrogen is a fuel that does not emit CO2 when burned, and we expect it to be available for ships. Therefore, we are conducting R & D of technology to use hydrogen as a fuel for marine gas engines. Hydrogen has the characteristic of readily igniting and subsequently burning at high speed. Therefore, to use hydrogen as a fuel, it is necessary to properly control this intense combustion characteristic of hydrogen during combustion in engines to achieve stable and safe operation. In our research, we installed the in-house hydrogen injection system to a spark-ignition lean burn type gas engine fueled by natural gas with a generating output of 400 kW, and hydrogen combustion experiments are underway. Based on previous experiments under conditions similar to those of hydrogen-only combustion, we demonstrated stable combustion, clean exhaust gas, and high thermal efficiency by making appropriate adjustments. As technologies to further reduce hydrogen combustion, we are also conducting research on EGR technology, which mixes exhaust gas with intake air for combustion, and water injection technology.

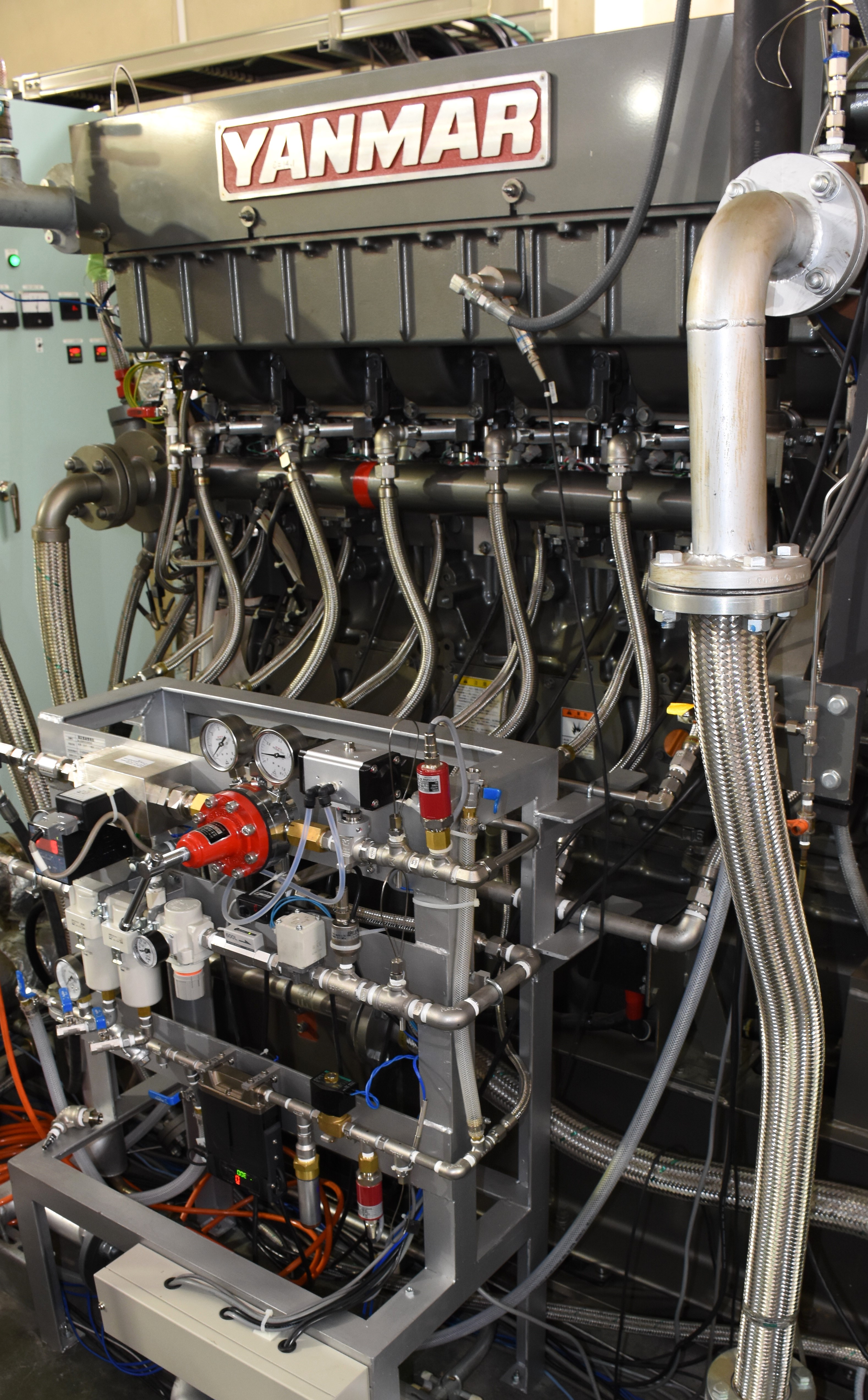

Engines and hydrogen supply facilities used in the study

Ammonia Fuel Utilization

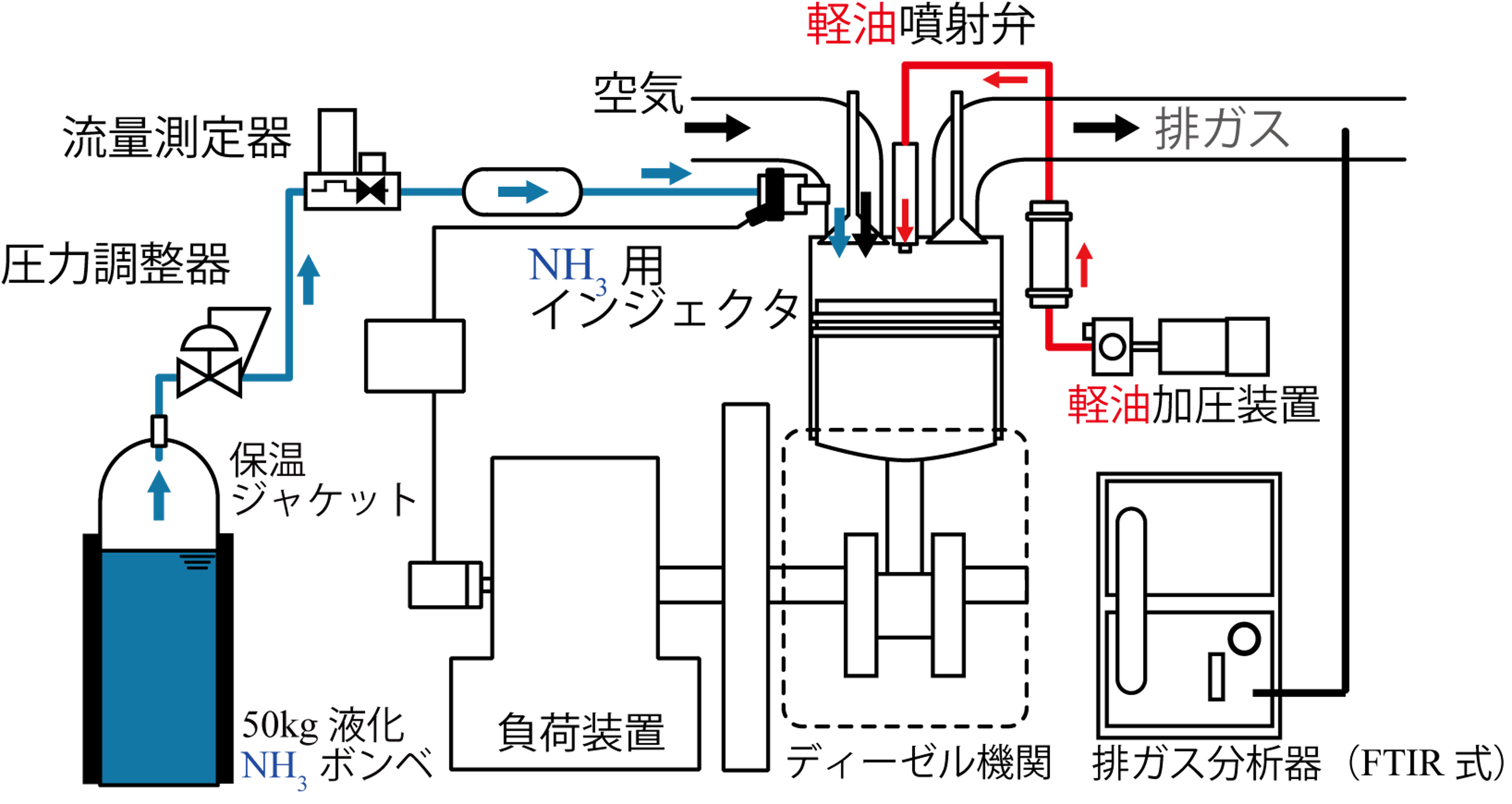

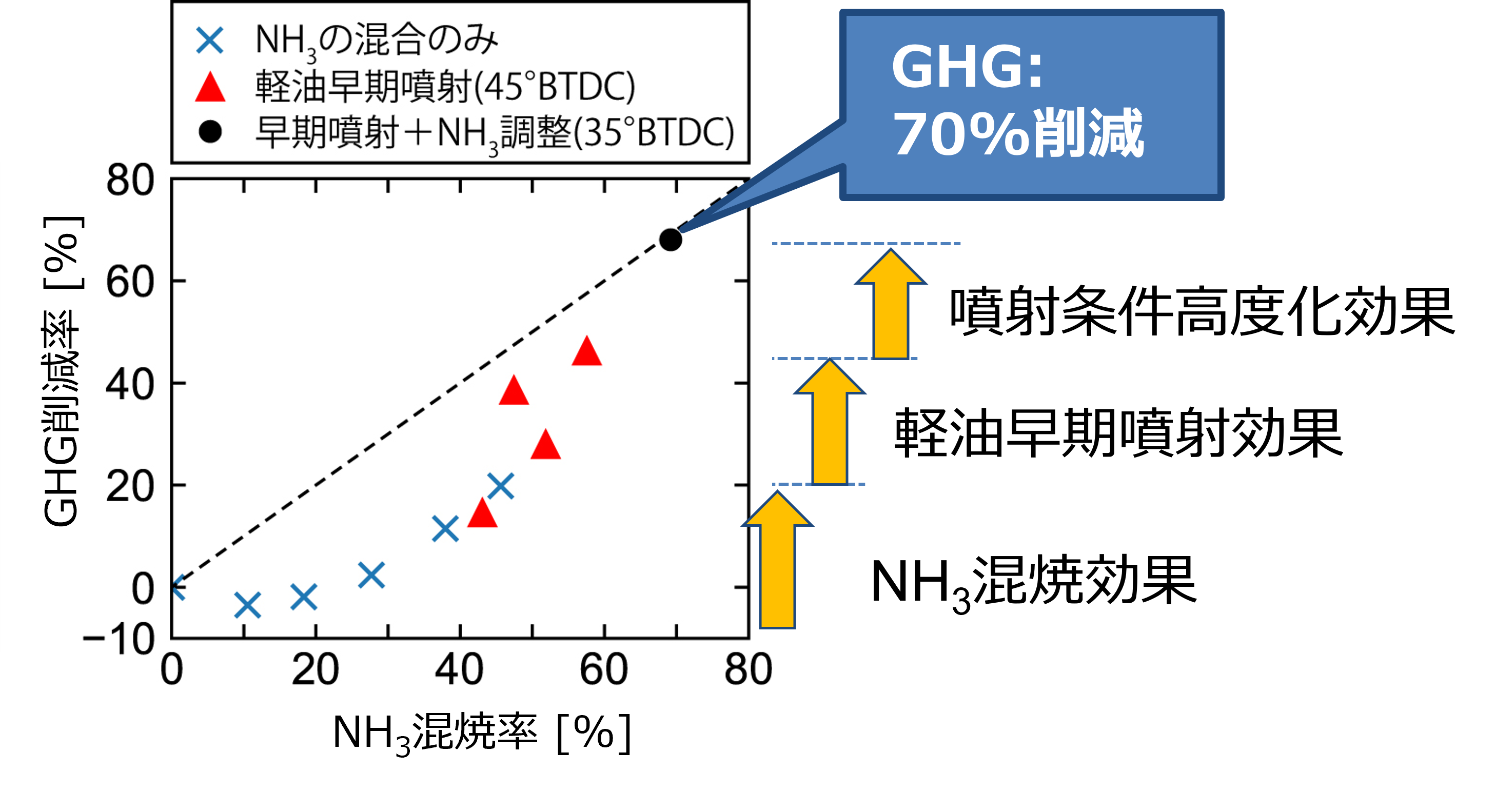

Ammonia (NH3) is a fuel that, like hydrogen, does not contain carbon and atom does not produce CO2 when burned. We can liquefy ammonia more readily than hydrogen, and liquefied ammonia's heating value per unit volume is about 1.6 times that of liquefied hydrogen, making it an excellent fuel for loading. From this viewpoint, it is attracting attention as an alternative fuel for ships. We have conducted fundamental experiments for ammonia fuel utilization with diesel engines to burn ammonia by ammonia and diesel fuel co-firing. Experiments revealed that unburned ammonia and nitrous oxide (N2O), a greenhouse gas, is emitted, and we conducted R & D on methods to reduce these emissions.

Future research includes a detailed analysis of the co-firing conditions of ammonia and diesel fuel and the development of a combustion strategy using hydrogen to enhance the combustion for safe and efficient ammonia combustion.

Ammonia and diesel fuel co-firing system

Example of

greenhouse gas (GHG) reduction rate evaluation

Plasma Utilization Technology

Plasma is the fourth state of matter along with solid, liquid, and gas. The plasma at atmospheric pressure is electrically ionized, which consists of a partially-ionized gas containing ions, electrons, and neutral atoms. In recent years, the atmospheric pressure plasma has attracted much attention for gas combustion assist and gas-reforming. Currently, we have also developed some plasma reactors. So far, we have confirmed that the developed microwave plasma reactor can convert the gases such as argon, nitrogen, air, methane, ammonia, and others into the plasma. We have investigated the performance and characteristics on the ammonia gas combustion assist and ammonia gas-reforming using the developed microwave plasma reactor.

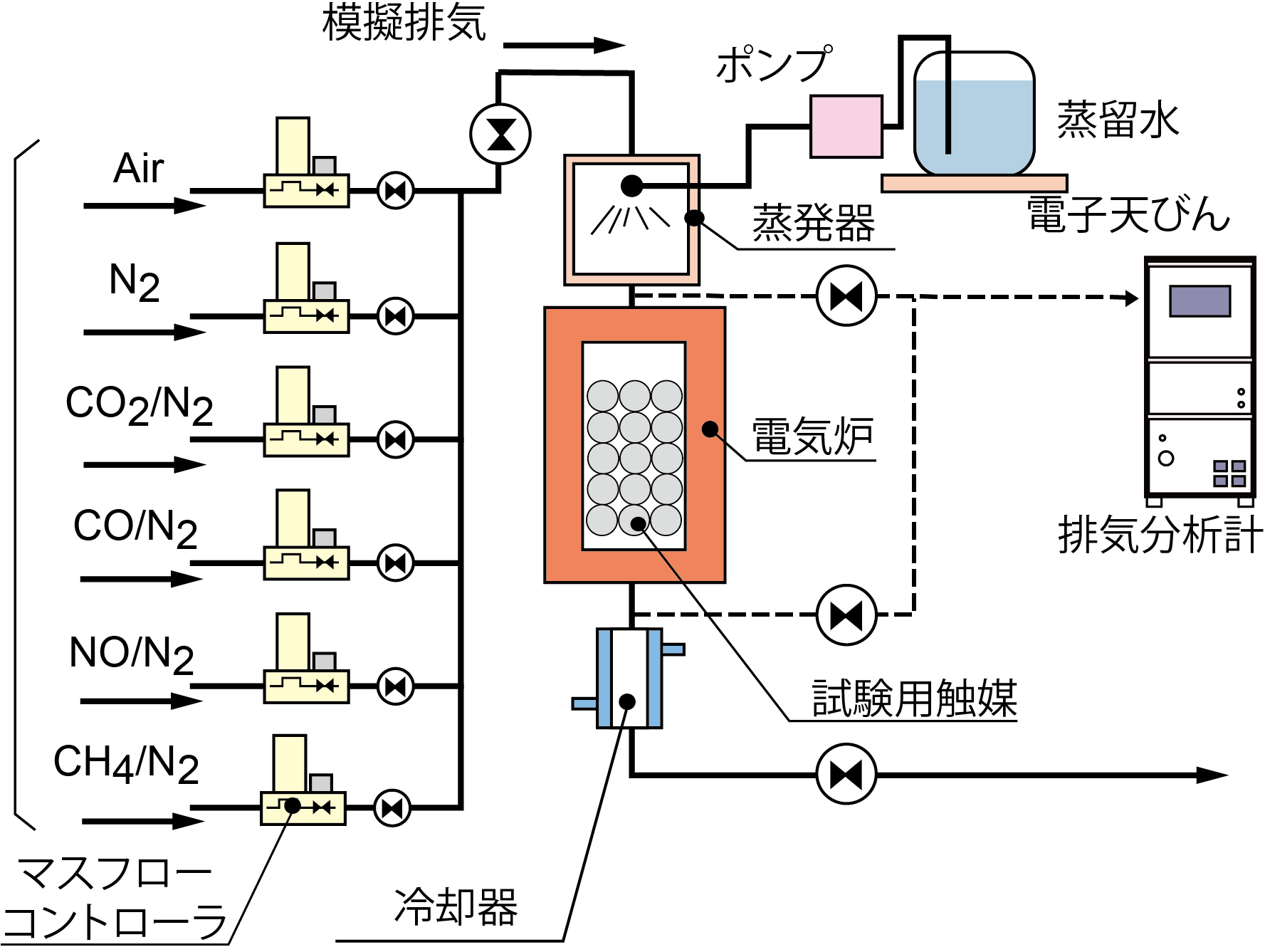

Exhaust Gas Purification by Catalyst

The engine emits gases (exhaust gases) after burning fuel. Because exhaust gases contain greenhouse gases and other pollutants, we reduce them by using catalysts as an aftertreatment system. We develop and evaluate the performance of catalysts by using a device called a microreactor (small plug flow reactor). The device can evaluate catalyst performance at any temperature and gas composition in simulated exhaust gases by mixing a number of gases from gas cylinders. To reproduce the moisture concentration in the exhaust gas, the microreactor has an evaporator to produce water vapor, which is fed with purified water. A small piece of the catalyst is cut from the actual catalyst used, and its performance is evaluated by analyzing the gas compositions at the inlet and outlet of the catalyst using an exhaust gas analyzer.

Microreactor (small plug flow reactor)