Development of Auxiliary Thrust Device for Model Test

— To control (apparent) resistance of model ship at will —

Research Overview

We are doing this kind of research. - easy explanations -

The ship receives resistance from the water as it moves forward. Most of this resistance is frictional resistance due to the water. Friction occurs when water flows over the ship's surface. The frictional resistance depends on the viscosity of the water. When a vessel moves forward, the propeller must generate enough forward force (thrust) to overcome the resistance, which is the same for an actual ship running in the ocean (full-scale ship) or a model ship running freely in a tank of fresh water (self-propelled model ship).

We conduct experiments by self-propelled model ships to investigate the performance of full-scale ship. The length of the model ship is about 3 to 4 meters. The phenomena that occur on the self-propelled model ship must be the same as those that happen on the full-scale ship but in the size of the model ship. That is, making the phenomena of a model ship similar to that of a full-scale ship (*1)."。

However, we cannot make the resistance of a model ship resemble that of a full-scale ship because, although the viscosity of fresh water is not much different from seawater, a model ship is much smaller than a full-scale ship, consequently, a model ship will run in relatively stickier water than a full-scale ship. The resistance of a 1/110th scale model ship (2.91 m long) of a 320 m long tanker reaches approximately 2.6 times that of a full-scale ship relatively. For this reason, the propeller of a self-propelled model ship must generate relatively more thrust than that of a full-scale ship to achieve a speed (*2) that is similar to that of a full-scale ship. If the resistance is not similar, the working conditions of the propellers will also be dissimilar. Furthermore, if the working condition of the propeller is not analogous, the rudder behind the propeller will also be dissimilar. As a result, we cannot examine the performance of the propeller and rudder of a full-scale ship by a self-propelled model ship (*3).

NMRI has developed a device that provides auxiliary thrust to make the apparent drag of a self-propelled model ship similar to that of a full-scale ship. This auxiliary thrust device uses a ducted fan to generate thrust by blowing air from the fan installed at the rear of the model ship. Although it does not change the actual resistance of the model ship, it can make the resistance of the model ship look similar to that of the full-scale ship (*4). In this way, we can make the thrust produced by the propeller of a model ship resemble that of a full-scale ship and examine the performance of a full-scale ship's propeller and rudder on a self-propelled model ship. The use of the auxiliary propulsion system is not limited to making the model ship's apparent drag similar to that of a full-scale ship. The auxiliary thrust can be set freely, allowing you to control the resistance and required propeller thrust of the self-propelled model vessel according to our objectives.

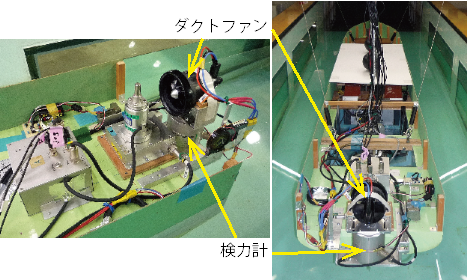

Figure 1 Duct fan type auxiliary thrust device

Figure 1 shows an auxiliary thruster mounted on a 3-meter-long container ship model. A ducted fan blows air out at high speed from the rear to provide auxiliary thrust to the model ship.

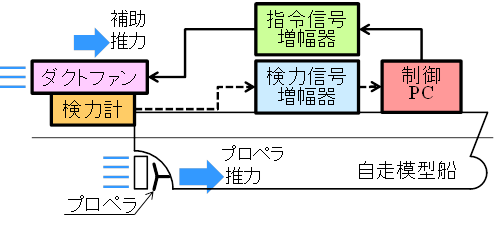

Figure 2 Configuration of auxiliary propulsion system

Figure 2 shows an example of instruments mounted on a model ship. The control PC controls the fan speed so that the auxiliary thrust measured by the force gauge matches the target value. The target value can also be varied depending on the speed of the model ship.

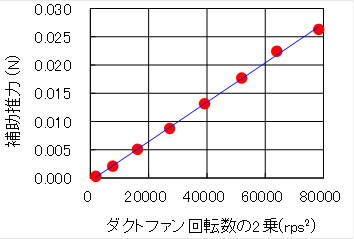

Figure 3 Relationship between duct fan speed and auxiliary thrust

Auxiliary thrust has easy-to-handle characteristics, as represented by the blue straight line. We use this characteristic to control the speed of the ducted fan.

Figure 4 Self-propelled model ship of a container ship running in a tank reproducing actual sea conditions using an auxiliary propulsion system

*1 Similarity here refers to matching the Froude number of the genuine ship and the model ship. The Froude number is a dimensionless value representing the ratio of gravity to inertia.

*2 When the Froude numbers are the same, the speed of the model ship is equal to the square root of the speed of the full-scale ship. For example, if the length of the model ship is 1/100th of that of the full-scale ship, the ship speed should be 1/10th.

*3 If the Reynolds number coincides between the full-scale ship and the model ship, the phenomena related to viscosity become similar. The Reynolds number represents the ratio of viscous force to inertia force. However, if the Reynolds number is to be matched, for example, when the length of the model ship is 1/100th of that of the full-scale ship, the speed of the model ship must be approximately 96 times faster than that of the full-scale ship. Such a speed is virtually impossible to achieve.

*4 This is called "friction modification." Until now, it has been very troublesome to perform friction correction on self-propelled model vessels.