Industrial System Research Group

INDUSTRIAL SYSTEM

This group has been advancing the "Digital Shipyard" concept to promote DX in the shipbuilding production processes. The Digital Shipyard concept aims to create a shipyard where everything is expressed numerically/planned numerically, and everything is completed according to plan, thus eliminating or digitalizing ambiguity that arises in various aspects of the shipbuilding process. This group is engaged in research and development related to the Digital Shipyard. As part of this effort, this group is developing a "Shipbuilding Simulator" that can precisely duplicate workers' flexible movements in shipbuilding work, including supplemental jobs. This group is committed to developing data linkage and standardization across shipbuilding design and production. In addition, AI utilization in shipbuilding design and planning is the target. Through these R & D efforts, this group aims to establish a framework that enables the construction of advanced ships with outstanding production efficiency.

Members

(◎: Head of the Group)

Research

Overview of our research

1. Study on construction of "Digital Shipyard"

This group conducts R & D of a "digital shipyard" aiming at "a shipyard where everything is numerically expressed/planned, and everything is completed as planned" toward realizing a short-term delivery of ships in a shipyard. In particular, this group is paying attention to information on the design and construction of shipbuilding. This group is engaged in research to create information related to design and construction and research to effectively transmit and display the obtained information to designers and workers.

- R & D of shipbuilding simulation technology that reproduces detailed movements of workers

- R & D of work support system for various shipbuilding works (bending, painting, etc.)

- R & D of application of AR technology and VR technology to shipbuilding

- R & D on shipbuilding robots (assistant work support robots, block surface plate management by drone, CFRP design CAD/CAM for shipbuilding, etc.)

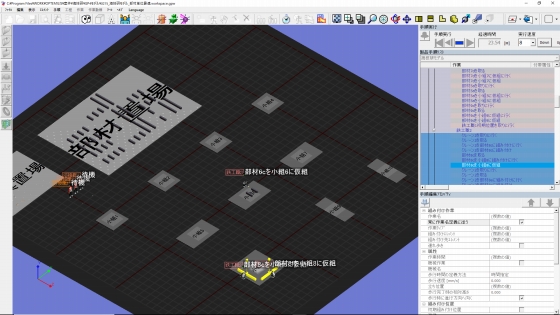

We are conducting R & D on shipbuilding simulation technology to reproduce the detailed movements of workers. Figure 1 shows a shipbuilding simulation that reproduces the detailed movements of the workers in a small assembly process. The practical application of such shipbuilding simulation technology enables the shipbuilding process to be precisely reproduced and helps plan worker allocation, calculate costs, and plan facility maintenance.

Fig.1 Example of shipbuilding simulation

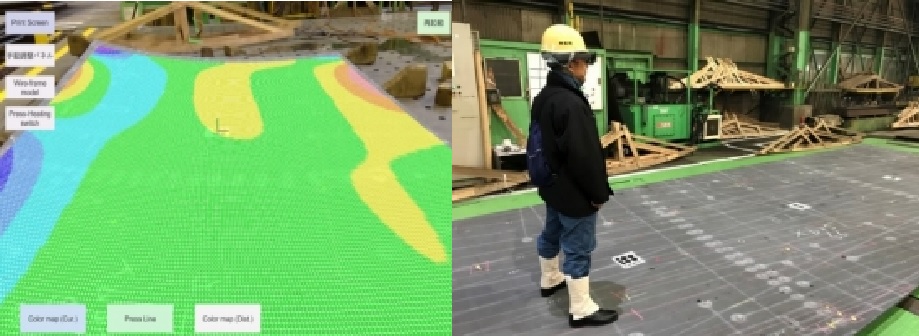

Shipbuilding involves various on-site operations such as bending steel plates, assembly, and painting. Workers on-site work while looking at the drawings, and we are engaged in research and development to support site operations using AR (Augmented Reality) technology, as shown in Fig. 2. The aim is to shorten the construction period by making the work more efficient.

Fig. 2 AR application to support bending process

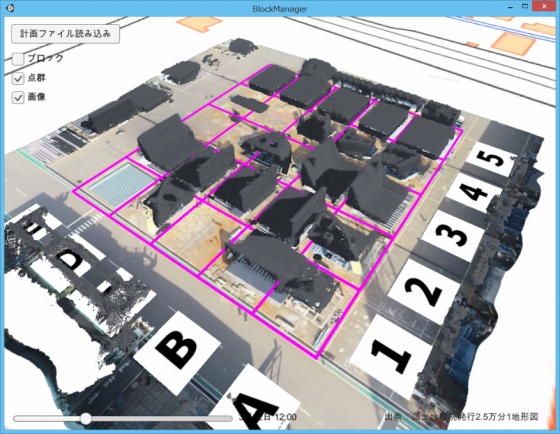

Ships are constructed by assembling parts of the hull structure, called blocks, on a surface plate. We have been developing the block surface management system shown in Fig. 3 to check whether the blocks under construction are manufactured as planned.

Fig.3 Block surface plate management system

2. Research on design and planning using AI (noise, nesting)

In today's world of the third AI boom, research and development using deep learning and deep reinforcement learning, which have evolved from neural network technology, is progressing. Also, connecting these AI technologies to social implementation is required in the current shipbuilding industry. Therefore, this group conducts research to utilize AI technology in the early stages of shipyard design (the stage of basic design and planning).

- Onboard noise prediction using neural networks

- Nesting by reinforcement learning (steel placement planning)

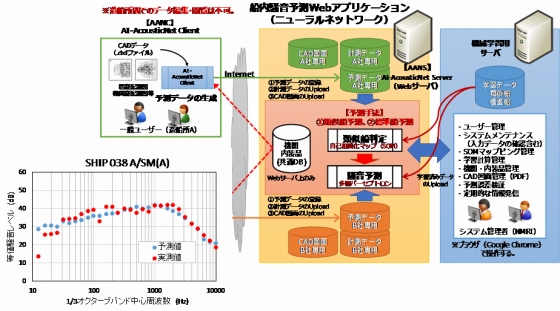

In the design stage, predicting the noise level inside a ship has been determined empirically and numerically. Simple and flexible empirical methods have been required to select and place components through trial and error in the design process. Neural network predictions are close to empirical judgments, so we have applied them to shipboard noise predictions. As shown in Figure 4, a web application is created, and all the sample data that will improve prediction accuracy is kept and controlled.

Fig. 4 Neural network based noise prediction web application and its operation image

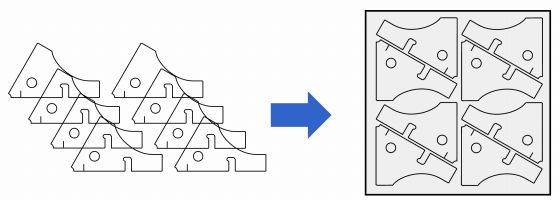

Nesting is arranging parts to reduce the amount of waste material as much as possible, as shown in Fig.5. We have tried to increase the yield rate at the design stage, and we have applied deep reinforcement learning, which is one of the learning methods of AI, to this task.

Fig.5 Nesting

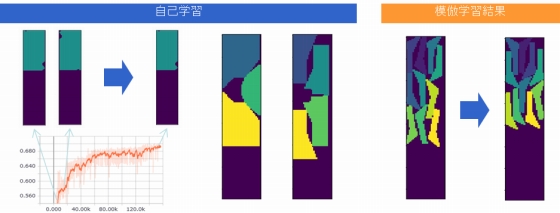

Figure 6 shows an example of AI nesting results. We obtained satisfactory results in self-learning without using results placed by humans. In contrast, by performing imitation learning using results placed by humans, we have confirmed the possibility that imitation learning can be used at a level that does not require manual correction.

Fig. 6 Nesting results by reinforcement learning

3. Research on Advancement of Inspection Technology

Visual inspection is the main form of detecting structural defects and damage. Recently, drones have been used as one means to get easy access to inspection points. This group has been working on the following research and development to apply them to the inspection of ship cargo tanks and offshore wind turbine blades.

- Image recognition of damage inside cargo tanks using deep learning AI

- Efficient method of inspecting offshore wind turbine blades

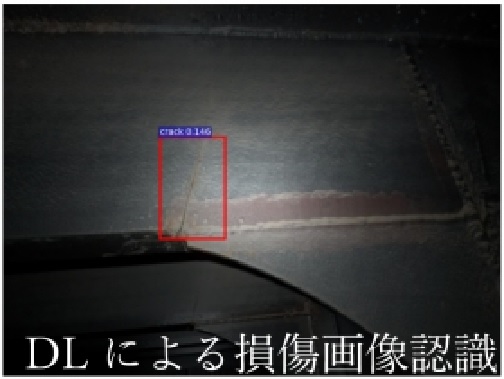

Assuming that drones are used to inspect the ship's internal structure, we studied utilizing image recognition using deep learning (Faster R-CNN) to find cracks. Figure 7 shows the result of damage recognition based on deep learning on the damaged images taken by an inspector with a digital camera. But, it is not sufficient to employ the current deep learning method alone for the field. It is necessary to advance this research by utilizing knowledge about important inspection points.

Fig. 7 An example of damage image recognition results by deep learning

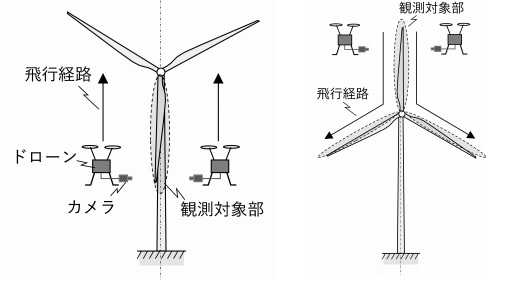

We are conducting research on efficient inspection technology for wind turbine blades to prevent the lowering of the operating rate of offshore wind power generation, which is expected to spread in the future. One of the inspection technologies is image inspection technology by drone. Offshore wind turbines are more severe to access than onshore wind turbines because they are installed offshore. Also, because the wind turbine itself is more giant than on land, the blades of the wind turbine are in a higher position, making visual inspection more difficult. We hope that image observation by drone will solve these problems. As an example, at the time of inspection, the wind turbine is stopped rotating, the drone shoots with the blade stationary, and the drone flight path for inspecting the front and back, and front and rear edges of the blade in a short time (Fig. 8) was examined.

Fig.8 Inspection method for offshore wind turbine blades