Research on the Safety and Operability Evaluation Technologies of Offloading Operations for Offshore Natural Gas Production Systems

Research Overview

Research Overview

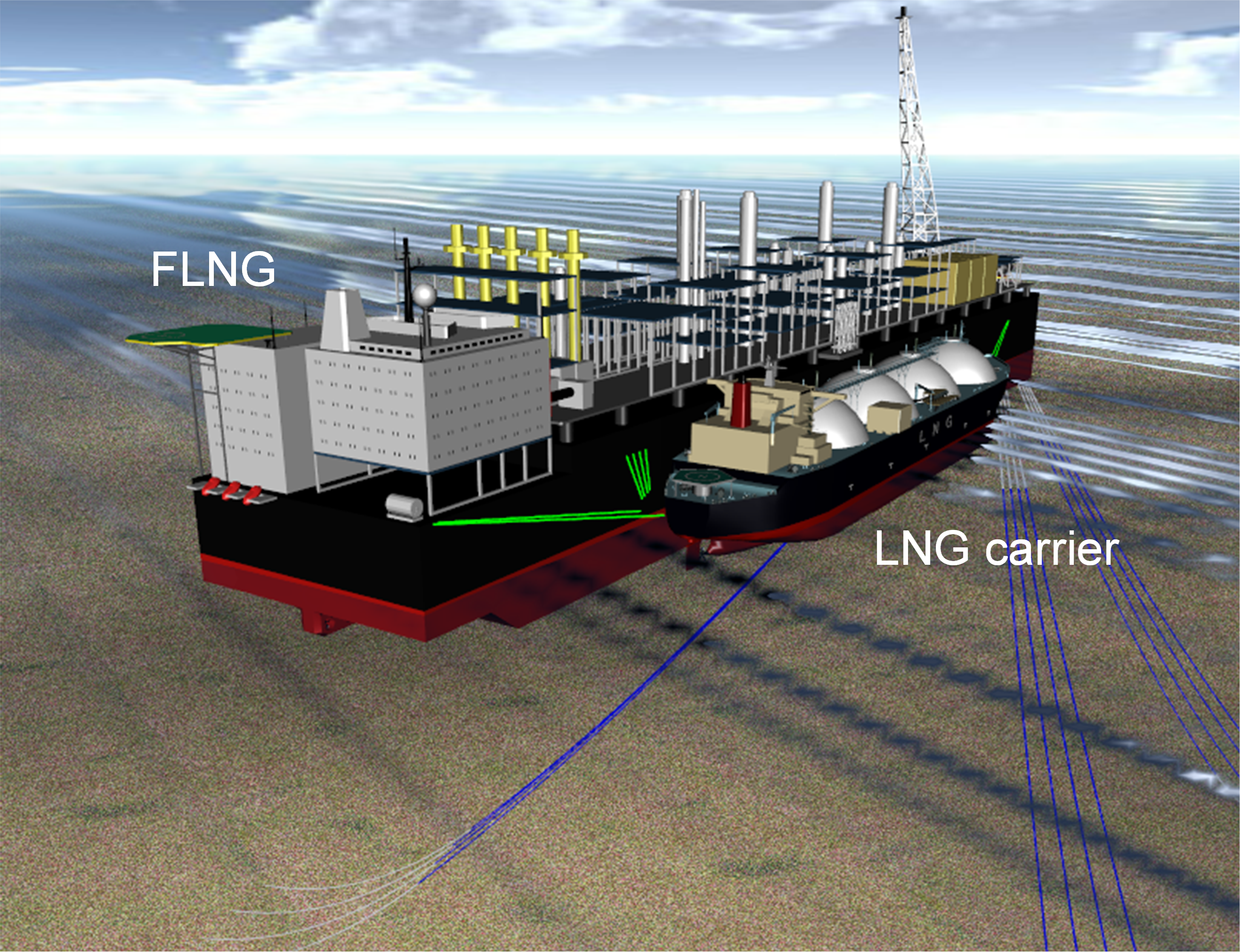

In recent years, natural gas has been increasingly expected to serve as an alternative resource to oil, meeting the needs for a stable energy supply and global environmental preservation. Various countries are researching to realize Floating Liquefied Natural Gas (FLNG) facilities and other systems. Companies like Petronas and Royal Dutch Shell have already begun operating FLNG units, but further technological development is needed to support continued progress.

The transfer of LNG (Liquefied Natural Gas) from FLNG to LNG carriers is a complex but essential offshore operation. From Japan's perspective of a stable energy supply, there is a growing need for offshore ship-to-ship LNG transfers. Thus, developing technologies for evaluating safety and operability will be crucial.

The Offshore Engineering System Research Group is developing a numerical simulation model that can analyze the integrated behavior of FLNG and LNG carriers, including the mooring lines and fenders connecting these two vessels. Moreover, the model includes the mooring systems connecting the FLNG to the seabed and the risers producing natural gas. The model also has an evaluation system for safety and operability that can contribute to offshore LNG transfer operations. In addition, as related elemental technologies, this group is working on a method for estimating environmental external forces, taking into account shielding effects, the effect of liquid behavior (sloshing) in the LNG storage tanks aboard FLNG and LNG carriers on the motion of the two vessels, and research on the evaluation of the behavior of LNG transfer hoses.

Model Tests (JSPS Grant–in–Aid for Scientific Research JP25289327)

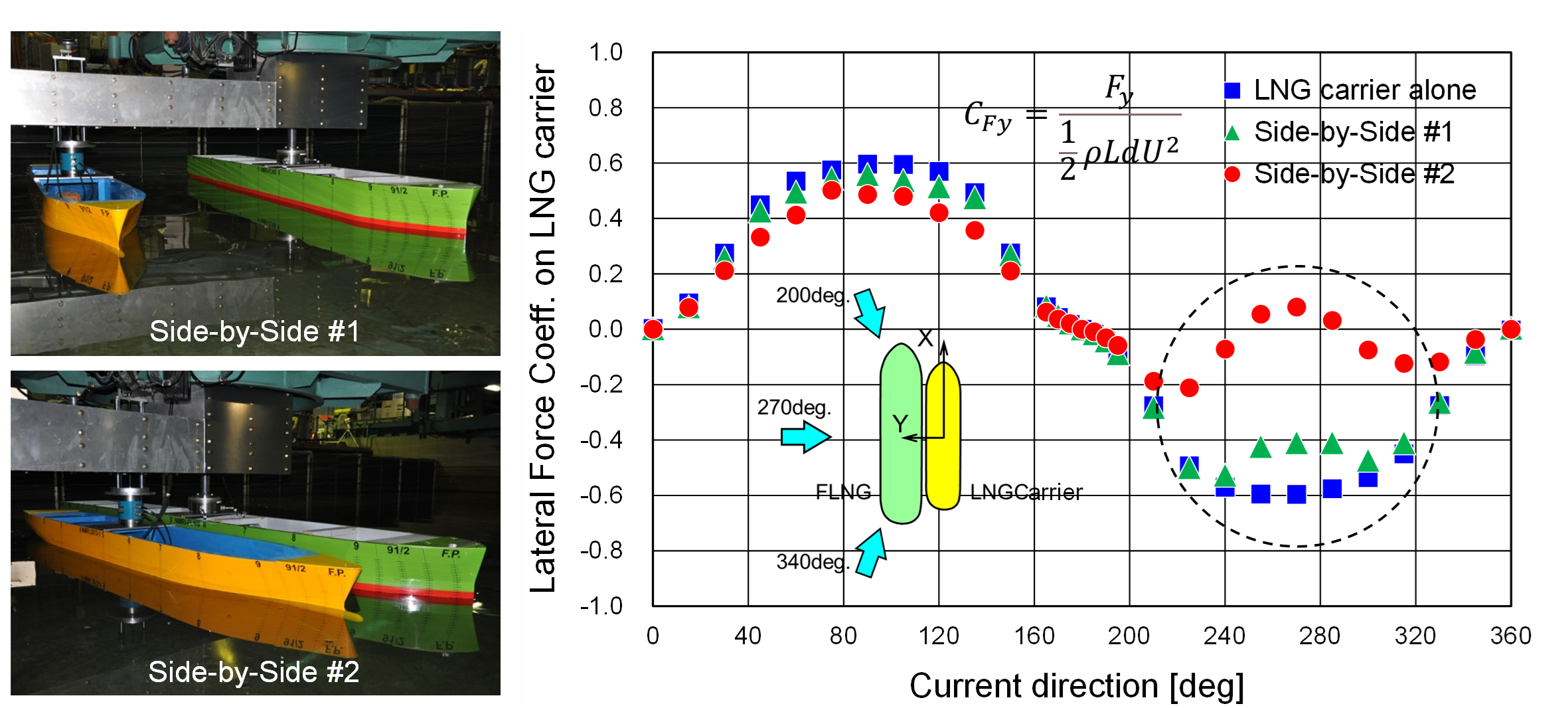

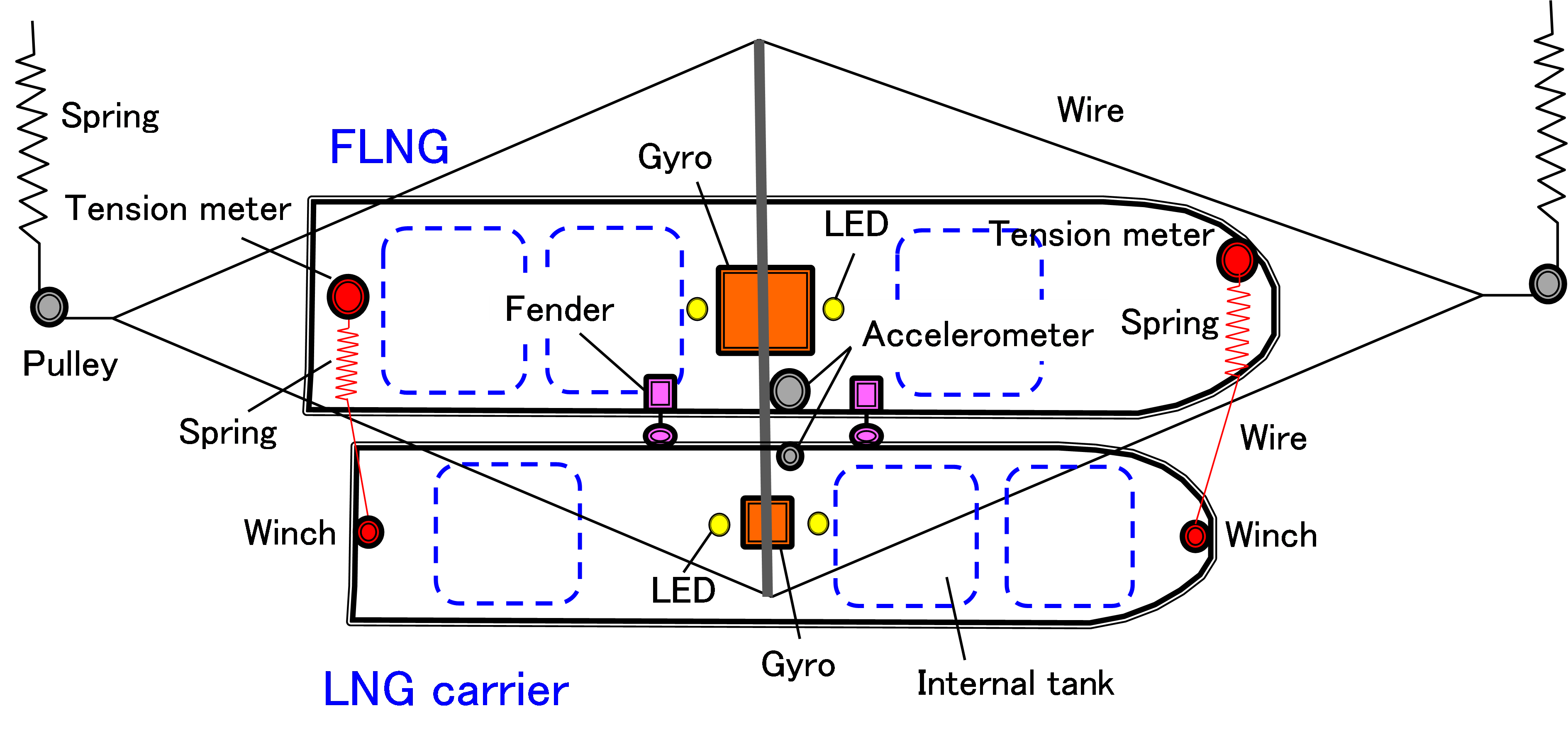

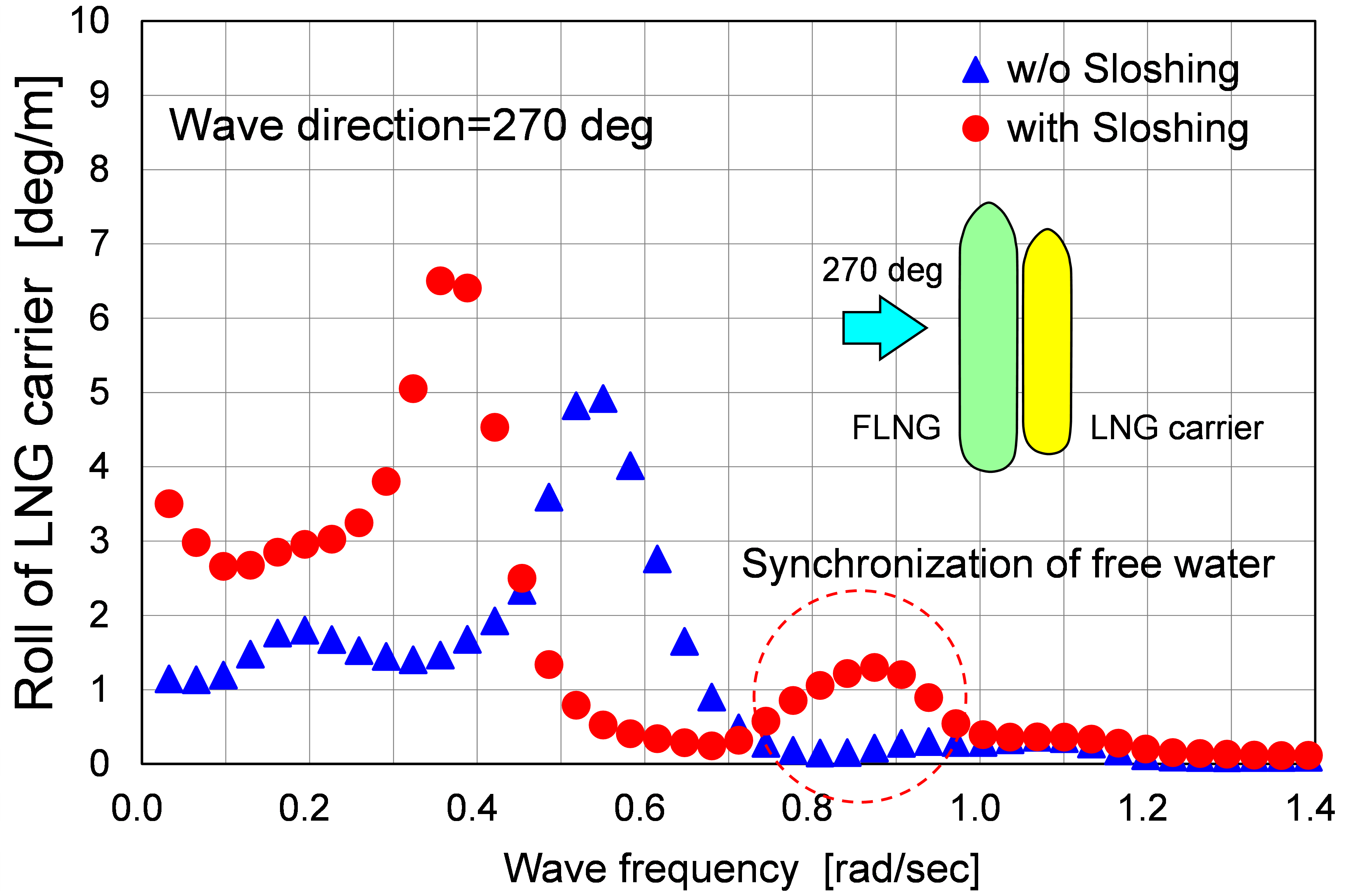

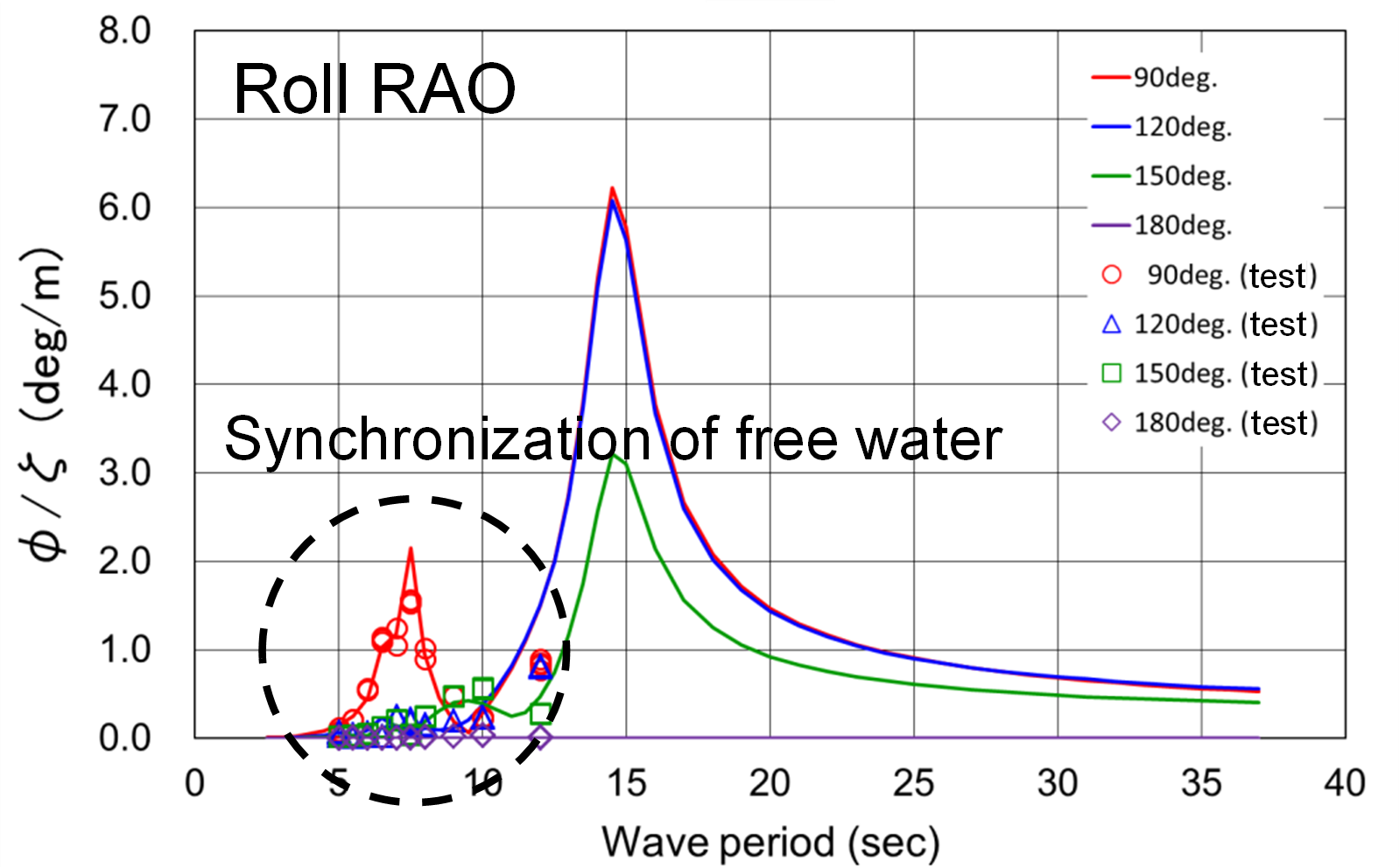

In the safety evaluation of a Side–by–Side moored FLNG and LNG carrier, it is necessary to evaluate the motion of these two vessels. In particular, when large vessels such as FLNG and LNG carriers are nearby, it is essential to consider the effects of mutual interference between the fluid forces acting on the hulls. In addition, both vessels have large LNG storage tanks. Thus, the sloshing effects in these tanks must be considered because these effects may result in a significant difference in the motion characteristics of the two hulls compared to the case where sloshing is not considered. The two vessels are connected by mooring lines and fenders, and considering the nonlinear characteristics of these connections, along with the sloshing effects, results in a complex problem where the hydrodynamic forces acting on the hulls also change.

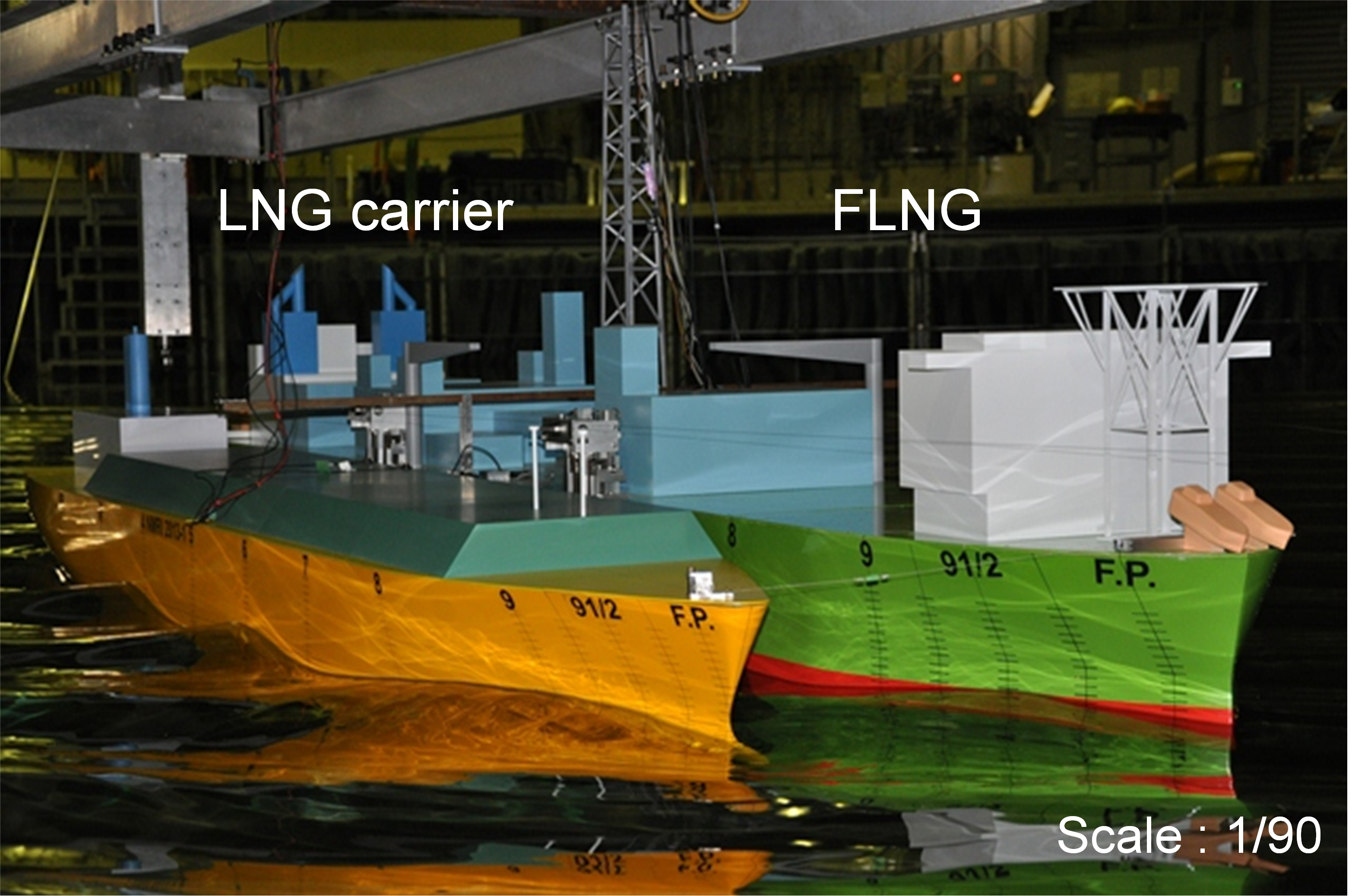

This group conducted captive towing tests with these two vessels using a reduced scale model (1/90 scale), assuming a half-loaded FLNG and an LNG carrier. In addition, we carried out the motion measurement tests in waves using both models. These tests examined the impact of hydrodynamic forces and sloshing on the motion response of the two vessels. Significant differences in low-frequency response were observed between cases that considered sloshing within the tanks and those that did not (using a gel to suppress water motion within the tanks). The effect of this difference in response to the availability of offshore LNG offloading operations is an issue for future study.

Figure 2 Oblique towing test of two ships in Side–by–Side configuration (left) and an example of measured lateral force coefficient acting on an LNG carrier (right)

Figure 4 Arrangement of internal tanks (right: FLNG, left: LNG carrier)

※ In the model tests, each tank was filled halfway with water and colored with food coloring.

Figure 7 Motion measurement test in waves considering the influence of sloshing water in the tanks and Response Amplitude Operator (RAO) of Roll motion

Reference

Yukawa, K., Fujiwara, T., Saito, M., Sato, H., Otsubo, K., Ishida, K., Watanabe, M., and Hasegawa, K.: Comprehensive Safety Evaluation Technology for Offshore Natural Gas Production Systems, Papers of National Maritime Research Institute, Vol.17, Num.2, pp.29-51, 2017 (in Japanese).

https://www.nmri.go.jp/service/repository_data/PNM21170203-00.pdf